Factory directly Plastic Chair Making Machine Injection Molding Machine

Bear "Customer first, Excellent first" in mind, we work closely with our shoppers and supply them with efficient and specialist services for Factory directly Plastic Chair Making Machine Injection Molding Machine, We are assured to generate excellent achievements in the upcoming. We are hunting forward to becoming one of the most reliable suppliers.

Bear "Customer first, Excellent first" in mind, we work closely with our shoppers and supply them with efficient and specialist services for Chair Injection Molding Machine, Plastic Chair Injection Molding Machine, Plastic Chair Making Machine, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

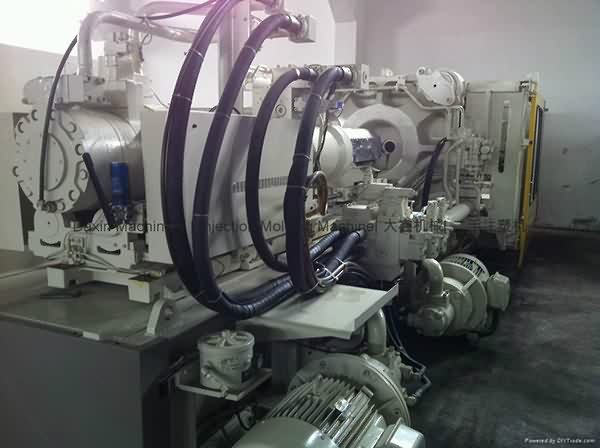

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT

Screw diameter: 80/95mm.

Tie bar spacing: 980mm.

Year: 2004、2003.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

1. The products of IB-Series have smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark. The machine is most suitable for manufacturing high quality products.

2. The mold design adopts the method of common mold base. Only by changing the mold parts, the product's shape, weight, or even the length can be changed. It saves time on mold alignment and doesn't require great expertise on mold changeover. Thus, it reduces the mold cost on manufacturing a wide range, but low volume of different applications.

3. The mechanical design is based on the blueprint of general-purpose injection molding machine. Hence, with general knowledge of injection molding machine, no matter machine operation or maintenance work can be handled with ease.

4. Applied materials include PC, PP, PE, PS, AS, PMMA, K-Resin, PET, PETG, TPR, PES, PCO and NYLON.

1993 Engel model ES 300/90TL plastic injection molding machine for sale at Hunter Plastics Inc. For more information click here: ...