Factory Selling 2013 Vertical Lsr Injection Molding Machine V55sd-lsr

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Factory Selling 2013 Vertical Lsr Injection Molding Machine V55sd-lsr, Our corporation is dedicated to furnishing customers with high and steady top quality products at aggressive price tag, making just about every customer glad with our services and products.

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Injection Molding Machine, Lsr Injection Molding Machine, Machine, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality solutions and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

Visit us after Chinaplas or Canton Fair!

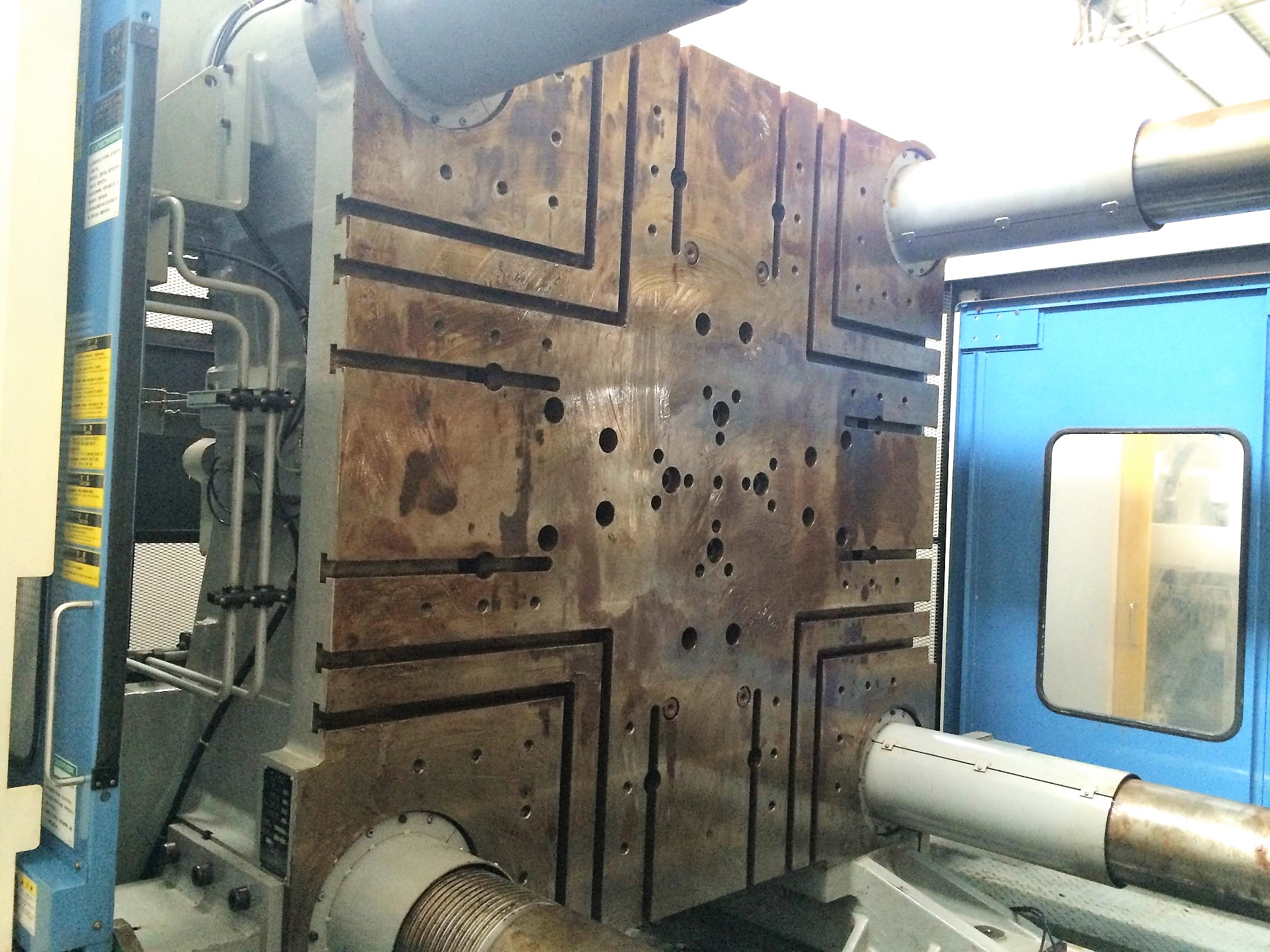

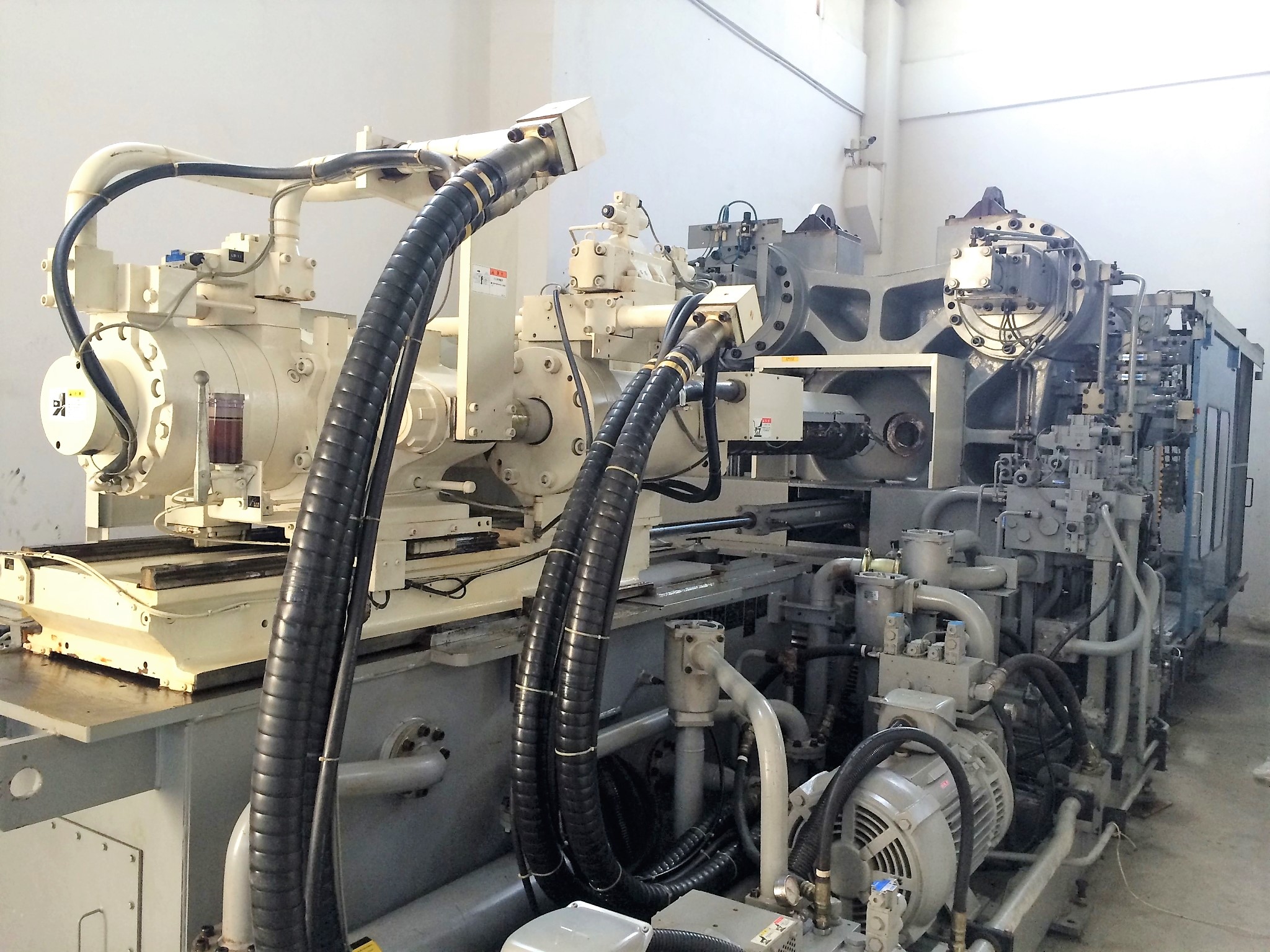

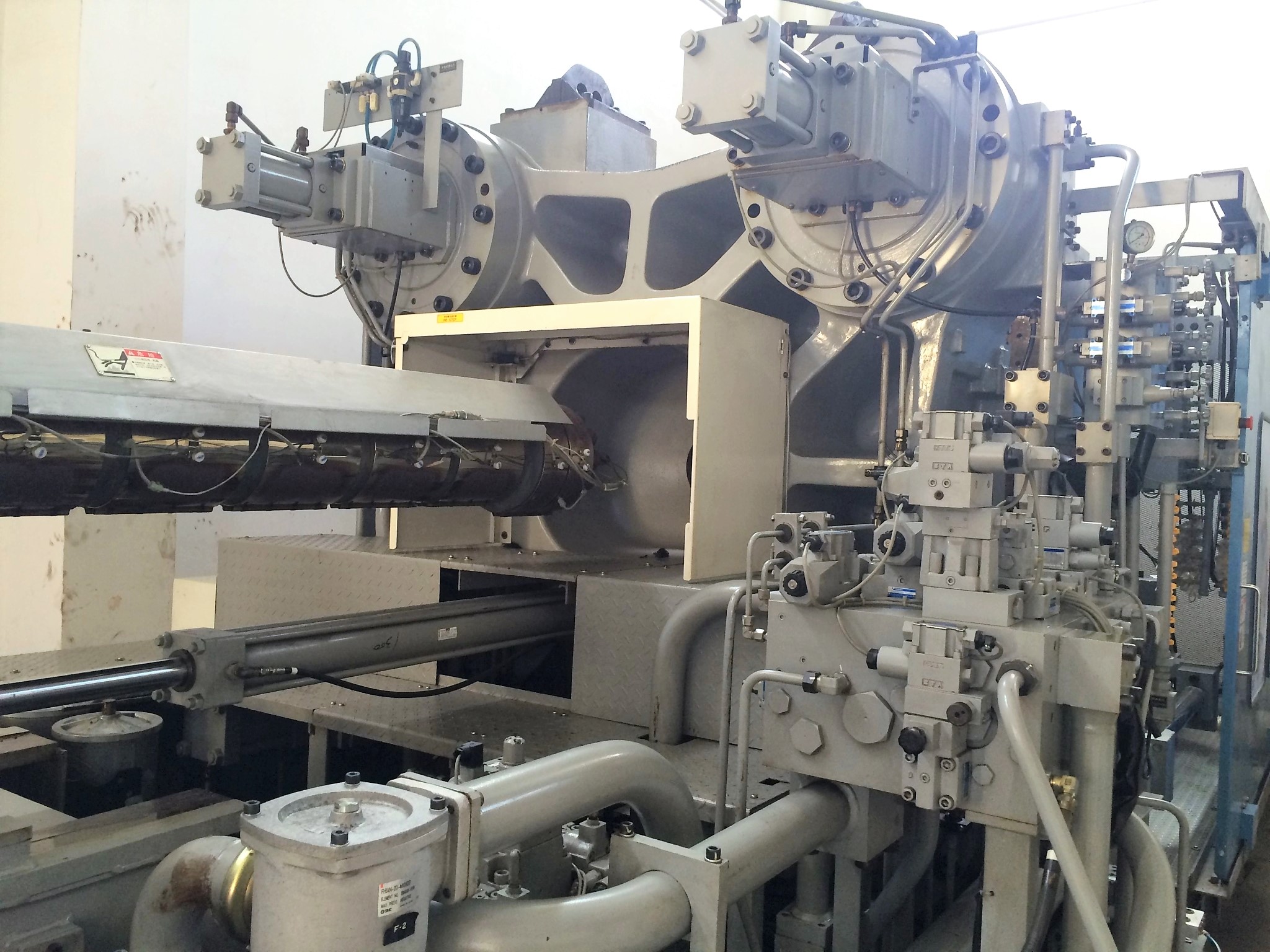

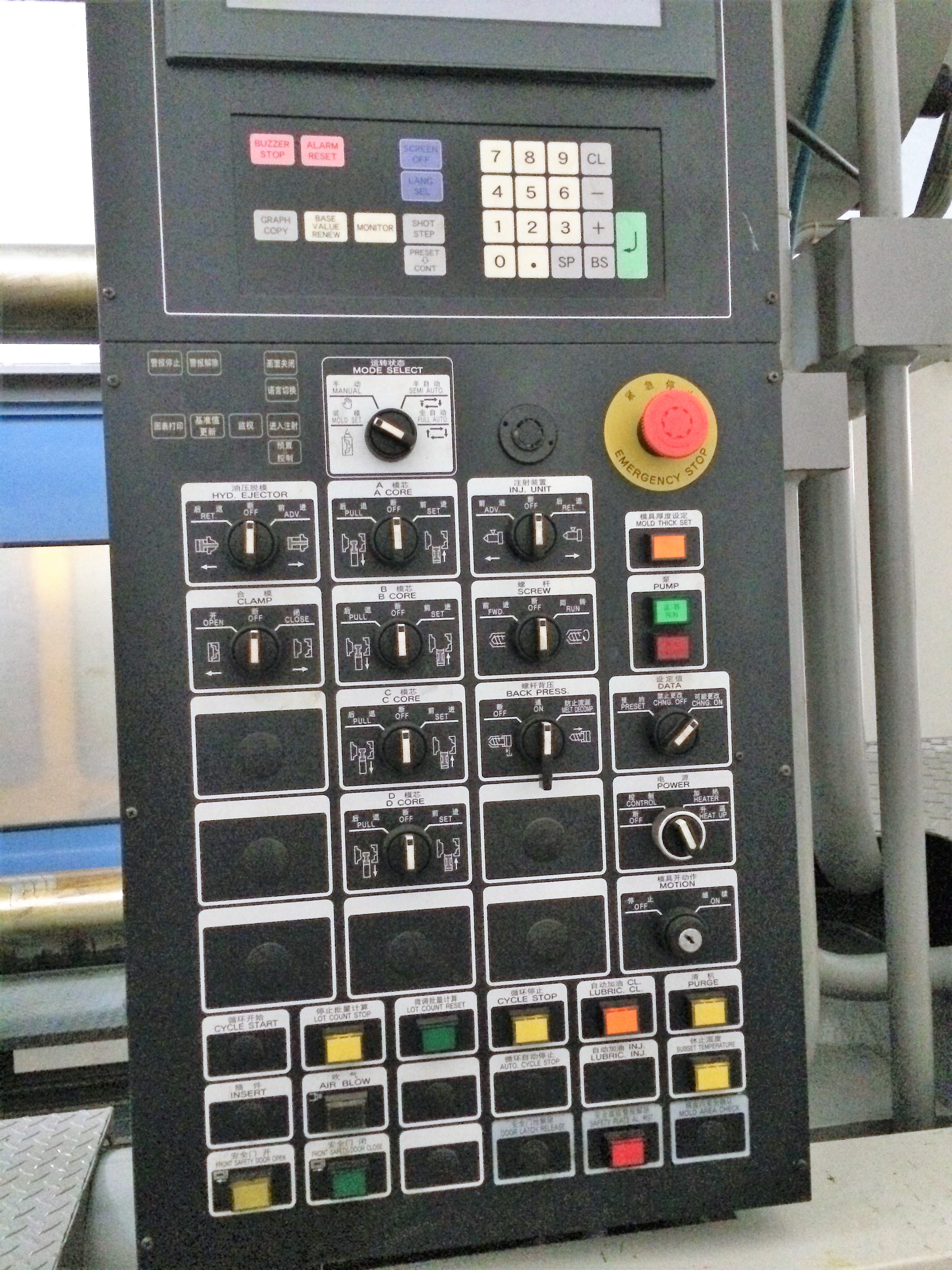

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is like new machine but half price of new machine price. It is in its origianl condition and original paint in the photos.

It is in very good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Why choose Daxin?

- Wide range of machines: Over 200 machines (20-2000t) in 10000 sqm warehouse (Largest collection of Japanese machines in China)

- Rich experience in export: one-stop solution including dismantling of machines, loading, moving, custom clearing (many agents cannot clear custom for used machines), shipment, assembling and commissioning of machines.

- All machines can be powered on for test-run. All machines can be viewed under one roof in our warehouse.

- Post-sale support: providing spare parts, commissioning machine, inputting program, repairing PCB boards or other machine parts

- Quality assured: All machines parts are checked thoroughly, including pumps, toggle, screw, barrel, oil seals, ball bearing, platen.etc.

- Any defective parts are repaired or replaced if beyond repair.

- Have exported to more than 30 countries : South East Asia, South Asia, Australia , Middle East, Africa, South America, Central America.

Product Image

In this video there is a introduce of the plastic molding and CAE technology`s development. C-mold for plastic mold simulation analysis software was the best one but annexed because a mistake made by an engineer.

20L Pail Forza PT450H Production Dry cycle

Máy ép nhựa Forza 450T ép thùng 20L (máy chạy không tải), với hệ thống dán nhãn bên trong IML, làm cho chu kỳ sản xuất ngắn hơn.

Liên hệ: 0909 725 216