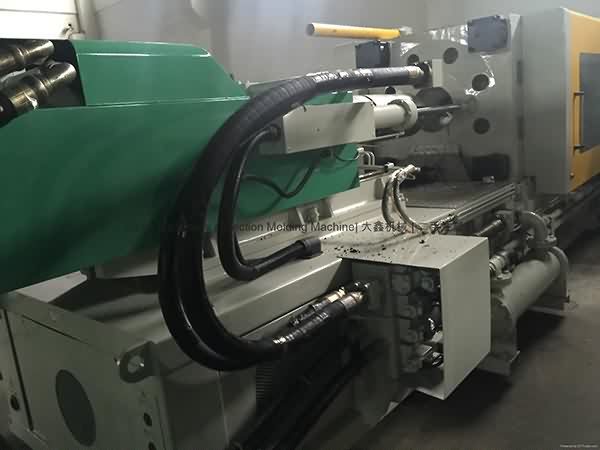

100% Original Chen Hsong Super Master SM450TS used Injection Molding Machine to Suriname Manufacturer

100% Original Chen Hsong Super Master SM450TS used Injection Molding Machine to Suriname Manufacturer Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

Bear "Customer initially, High quality first" in mind, we do the job closely with our customers and supply them with efficient and skilled providers for 100% Original Chen Hsong Super Master SM450TS used Injection Molding Machine to Suriname Manufacturer, The product will supply to all over the world, such as: Finland , Italy , Mumbai , Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

Huaao Electricity Technology Co.,Ltd is the only supplier who professional produce: APG machine,APG molds,casting mold and instrument transformer winding ...

THE MACHINE HAS BEEN SOLD

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.