100% Original Chuan Lih Fa CLF-1000T used Injection Molding Machine to Seychelles Factories

100% Original Chuan Lih Fa CLF-1000T used Injection Molding Machine to Seychelles Factories Detail:

Chuan Lih Fa 1000t used Plastic Injection Molding Machine.

Youtube Video: https://youtu.be/woC2fZ-o8zA

Model: CLF-1000T.

Year: 2006.

Screw diameter: 105mm.

Tie bar spacing: 1050x990mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

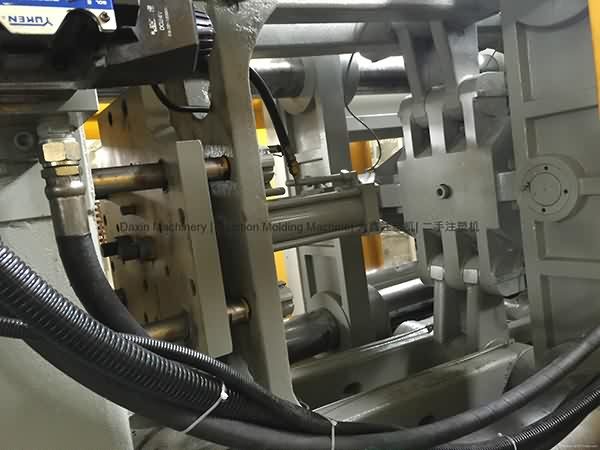

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

We take pleasure in a really excellent name amongst our shoppers for our exceptional product or service excellent, competitive rate and also the greatest services for 100% Original Chuan Lih Fa CLF-1000T used Injection Molding Machine to Seychelles Factories, The product will supply to all over the world, such as: Hungary , Sri Lanka , Swaziland , As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

For more information reach me at gaur_arvind@yahoo.com

call me at +91-9357773797

Visit: www.gaurtrader.com

Manufacturer: Toshiba Model No.: 840M71/ISF90PVL Inventory No.: 0616-226-0107 Aisle: 12A Weight (lbs.): 8215 Price (current as of 7/12/16): $4999 15'' x 23'' ...

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.