100% Original Factory Niigata 180t used All-electric Injection Molding Machine to Korea Factory

100% Original Factory Niigata 180t used All-electric Injection Molding Machine to Korea Factory Detail:

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

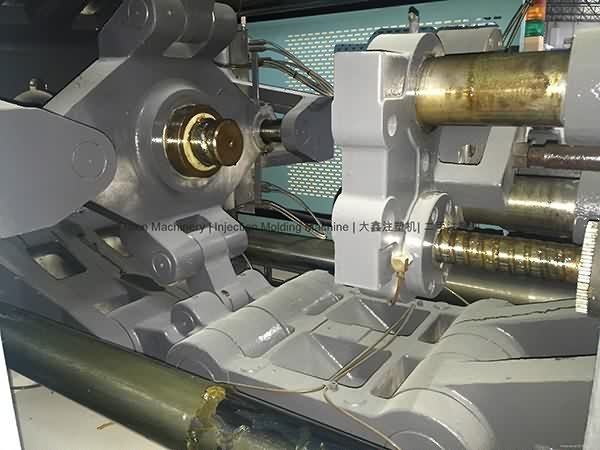

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for 100% Original Factory Niigata 180t used All-electric Injection Molding Machine to Korea Factory, The product will supply to all over the world, such as: Malta , United Arab Emirates , Cape Town , Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Dakumar hybrid high speed injection machine for thin wall mould tryout. for more information about that injection machine, pls send inquiry to ...

All electric of blowing and injection molding machine.

Magic it is the leader in Full Electric machine.

Model ME = Magic Electric

Model MTM = Mechatronic machine

You can find us in:

www.magicmp.it - Italian website

www.magicnorthamerica.com - North America website

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.