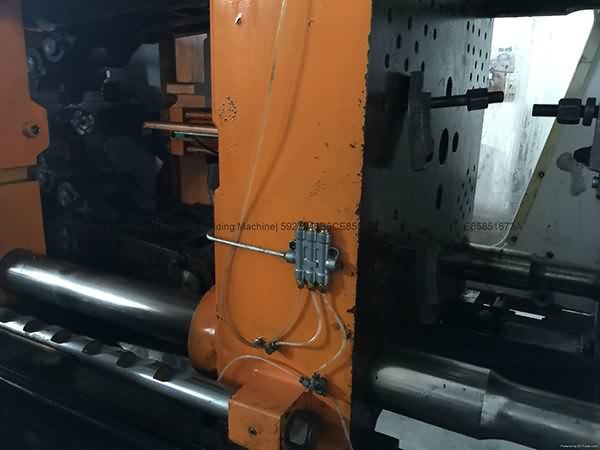

100% Original Nanrong 250t used Injection Molding Machine for Jakarta Importers

100% Original Nanrong 250t used Injection Molding Machine for Jakarta Importers Detail:

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

To meet the customers' over-expected pleasure , we have now our solid crew to supply our greatest all round assistance which includes marketing, sales, planning, production, top quality controlling, packing, warehousing and logistics for 100% Original Nanrong 250t used Injection Molding Machine for Jakarta Importers, The product will supply to all over the world, such as: kazakhstan , Serbia , Yemen , We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

Wetec Europe Otomasyon

www.wetec.com.tr

Automatic Bottle Making Machine

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!