18 Years Factory Haitian 120t used Injection Molding Machine for Jeddah Importers

18 Years Factory Haitian 120t used Injection Molding Machine for Jeddah Importers Detail:

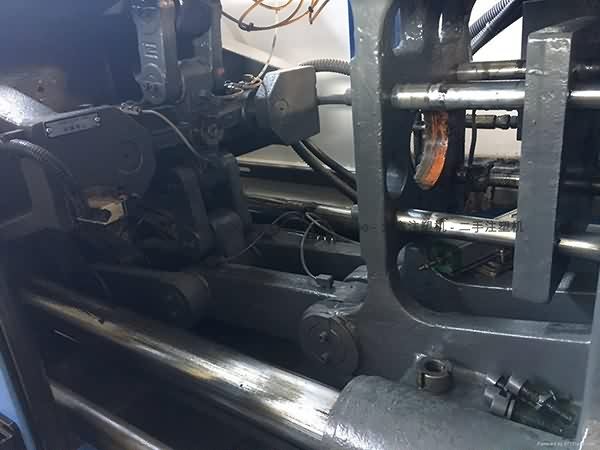

Haitian 120t used Injection Molding Machine

Model: SA1200/370.

Year: 2010.

Screw: A-D34.

Tie bar spacing: 410mm.

Two units. Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

We believe that prolonged time period partnership is really a result of top of the range, benefit added provider, prosperous knowledge and personal contact for 18 Years Factory Haitian 120t used Injection Molding Machine for Jeddah Importers, The product will supply to all over the world, such as: Japan , Orlando , Paraguay , Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

Dakumar hybrid high speed injection machine for thin wall mould tryout. for more information about that injection machine, pls send inquiry to ...

https://www.gpa-automation.com

● Macchina dimostrativa delle tre tecnologie di pressatura della G.P.A. ITALIANA composta da:

- pressa pneumatica PRNA 500 (4,2 kN a 6 bar),

- pressa idro-pneumatica PCM 4000 con regolazione totale della corsa (33,6 kN a 6 bar),

- pressa elettrica CP 50 (50 kN)

- tavola rotante elettro-meccanica

Abbinate ad un sistema di controllo qualità con:

- sistema di visione Keyence per analisi immagine

- sistema di controllo forza-corsa

- memorizzazione dati di processo

G.P.A. ITALIANA progetta e costruisce attrezzature personalizzate nelle quali, sempre più spesso, sono presenti le proprie presse elettriche.

● Demonstration machine of the three G.P.A. ITALIANA pressing technologies:

- pneumatic press PRNA 500 (4.2 kN at 6 bar)

- hydro-pneumatic press PCM 4000 with total stroke adjustment (33.6 kN at 6 bar)

- CP 50 servo press (50 kN)

- electro-mechanical rotary table

Combined with a quality control system composed by:

- Keyence vision system for image analysis

- a force-stroke monitoring system

- process data storage

G.P.A. ITALIANA designs and constructs customized equipment in which, more and more often, are used own servo presses.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.