18 Years Factory JSWJ1600EIII used Injection Molding Machine to Malaysia Importers

18 Years Factory JSWJ1600EIII used Injection Molding Machine to Malaysia Importers Detail:

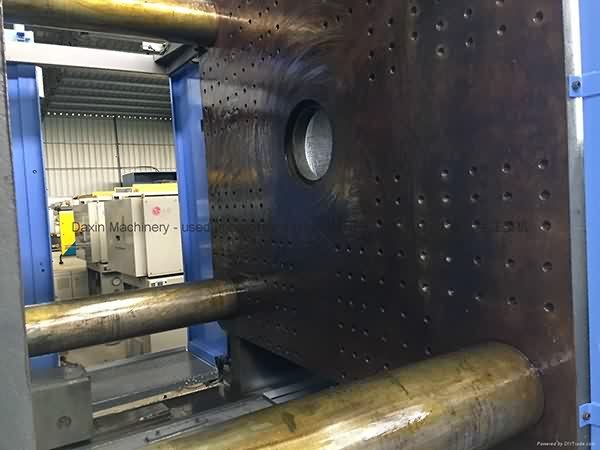

JSW 1600t used injection molding machine.

Model: J1600EIII.

Year: 2008.

Tie bar spacing: 1530x1280mm.

Screw diameter: 140mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for 18 Years Factory JSWJ1600EIII used Injection Molding Machine to Malaysia Importers, The product will supply to all over the world, such as: San Francisco , Vietnam , Porto , Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

2,500 Ton Danly Stamping Press For Sale For Sale 616-200-4308, For up to date detials stock visit our website https://d3r5f9xr0rb0d5.cloudfront.net/ We buy and sell presses and feeders. If you have equipment for sale please contact us.

https://youtube.com/watch?v=K7vPBH7bKxQ

What's App: +86 159 6280 7500

Wechat: bobomachine

Email: sotu@bobomachine.com

Tel: 0086 513 8907 7744

Fax: 0086 513 8907 7745

Website: www.bobomachine.com

Stainless steel cutlery, flatware, fork, knife and spoon making machine from BOBO Machine, China.

Contact us for more detailed information.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!