2017 China New Design Hwa Chin 160t two-color used Injection Molding Machine Export to Malawi

2017 China New Design Hwa Chin 160t two-color used Injection Molding Machine Export to Malawi Detail:

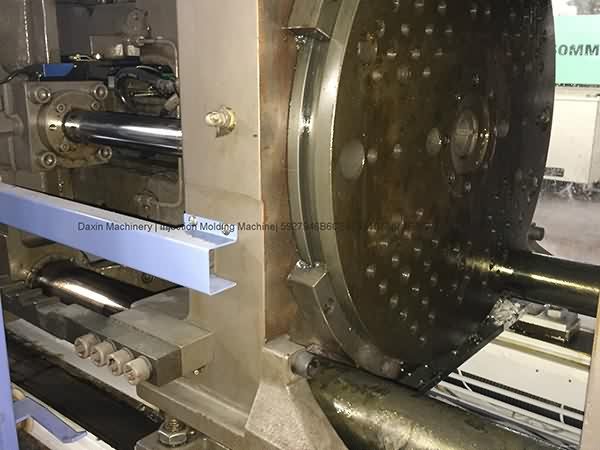

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We keep on with our business spirit of "Quality, Performance, Innovation and Integrity". We goal to create much more worth for our customers with our rich resources, state-of-the-art machinery, experienced workers and exceptional providers for 2017 China New Design Hwa Chin 160t two-color used Injection Molding Machine Export to Malawi, The product will supply to all over the world, such as: Serbia , Guatemala , Dubai , We warmly welcome your patronage and will serve our clients both at home and abroad with products of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

Exclusive Repairs @ Advanced Micro Services Pvt,Ltd,www.amsindia.net,

Contact Person:MalateshPatil,+919900565861,patil@amsindia.net

Address: Advanced Micro Services Pvt. Ltd

# 305,3rd Floor,Annexe-E Block,Brigade MM,Jayanagar,7th Block K R Road, Bangalore-560082, India

Website:www.amsindia.net

Techspan New Zealand have represnted ENGEL since 1979 -

In this video - ENGEL easix - the multifunctional 6-axis robot

Working with ease in all three dimensions: The ENGEL easix six-axis robot and its integrated control unit are ideally equipped for current and future tasks, making your production even more efficient. No matter whether you need a particularly flexible automation solution or face special requirements, such as cleanroom production.

Further information: https://www.techspan.co.nz/engel/

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!