2017 China New Design Toshiba IS650GT Used Injection Molding Machine for Estonia Factories

2017 China New Design Toshiba IS650GT Used Injection Molding Machine for Estonia Factories Detail:

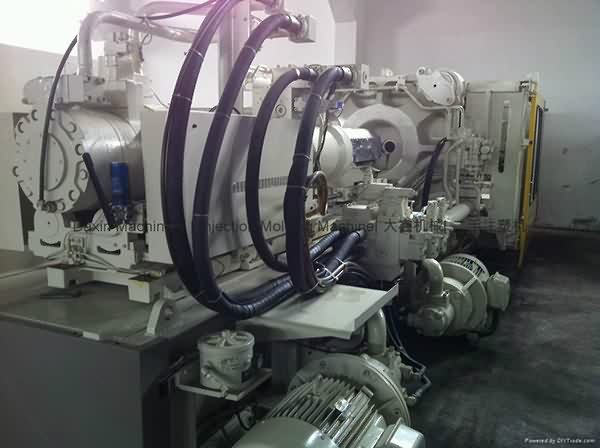

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for 2017 China New Design Toshiba IS650GT Used Injection Molding Machine for Estonia Factories, The product will supply to all over the world, such as: Singapore , Eindhoven , Atlanta , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Water Damage Restoration? Bay Shore, NY Call (631) 888-6080 Open 24/7, Call Us at (631) 888-6080, or visit our website for more info. Open 24 Hours For Emergencies.

https://westbabylonrestorationpros.com/

https://youtube.com/watch?v=5BSnwS1DtsU

Miles travels through Amish country while Bob tries to understand Miles weird neighbors. Come see Flat Manny, the amazing paper mail carrier! It's finally here ...

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.