2017 China New Design Toshiba IS650GT Used Injection Molding Machine Supply to Albania

2017 China New Design Toshiba IS650GT Used Injection Molding Machine Supply to Albania Detail:

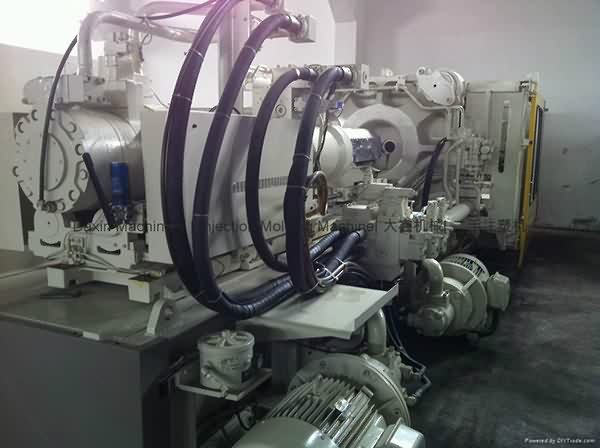

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for 2017 China New Design Toshiba IS650GT Used Injection Molding Machine Supply to Albania, The product will supply to all over the world, such as: Washington , USA , Ghana , Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

ENGEL victory 120 combi. Combination of technologies. IML in mold labelling + metal insert molding +combiment for injection of 2 different materials (hard and ...

Gia cong ép nhựa giá rẻ toàn quốc số lượng ít 100- 1000 Sp theo yêu cầu 0932668186 Tuấn.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.