2017 Good Quality Chen Hsong Super Master SM450TS used Injection Molding Machine to San Diego Manufacturer

2017 Good Quality Chen Hsong Super Master SM450TS used Injection Molding Machine to San Diego Manufacturer Detail:

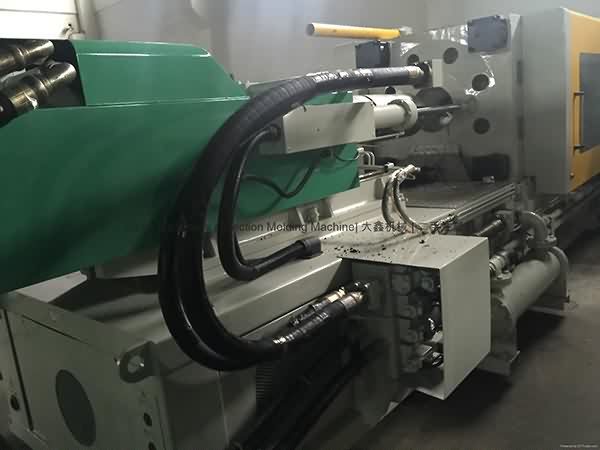

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for 2017 Good Quality Chen Hsong Super Master SM450TS used Injection Molding Machine to San Diego Manufacturer, The product will supply to all over the world, such as: Mongolia , UK , Brazil , With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we're trying our best to be your good partner.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.