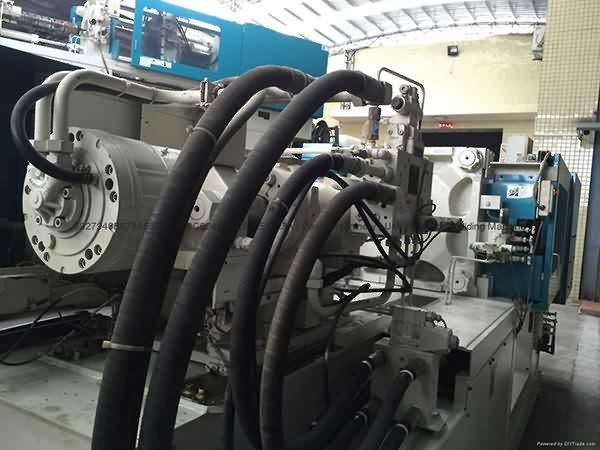

2017 Good Quality Mitsubishi 160t used Injection Molding Machine Export to Sweden

2017 Good Quality Mitsubishi 160t used Injection Molding Machine Export to Sweden Detail:

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for 2017 Good Quality Mitsubishi 160t used Injection Molding Machine Export to Sweden, The product will supply to all over the world, such as: Croatia , Jamaica , Riyadh , Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

call now +919872428844 (whats app available) gautam aggarwal

We are glad to introduce ourselves "prem nath & brothers"as one of the Leading manufaturer of Construction Equipments and Building Material Machineries since the year 1961 . We also take pride in being the largest Export & Import house.

Brick Making Plants,concrete brick machine,bricks machine,cement brick maker,bricks manufacturing plant,bricks manufacturing plant in jammu,bricks manufacturing machinery,bricks manufacturing machinery in punjab,bricks making plant in punjab,v,v,bricks maker plant in punjab,bricks manufacturing plant in kashmir,concrete bricks making video ,cemet bricks manufacturing plant in punjab,concrete bricks manufacturing in punjab,bricks manufacturing ,bricks manufacturing machine,bricks manufacturing plant in india,bricks manufacturing plants

We assure you the Best Quality of our products and after sale-service for years to come.. We hope that you will give us an opportunity for supplying your esteemed organization with the above machinery.

Thanking and eagerly awaiting your valued response.

Website - https://www.machinerymanufacture.com

https://www.flyashbrickmachinery.in

we also export to

Afghanistan Albania Algeria Angola Antigua and Barbuda Argentina Armenia Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Beliz Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil

Brunei BulgariaBurkina Faso Burma Burundi Cambodia Cameroon Cape Verde Central African Republic Chad Chile Colombia Comoros Democratic Republic of the Congo Republic of the Congo Costa Rica Côte d'Ivoire

Croatia Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea

Eritrea Ethiopia Fiji Gabon The Gambia Georgia Ghana Grenada Guatemala Guinea Guinea-Bissau

Guyana Haiti Honduras Hungary India Indonesia Iran Iraq Jamaica

Jordan

Kazakhstan

Kenya

Kiribati

Kyrgyzstan

Laos

Lebanon

Lesotho

Liberia

Libya

Macedonia

Madagascar

Malawi

Malaysia

Maldives

Mali

Marshall Islands

Mauritania

Mauritius

Mexico

Federated States of Micronesia

Moldova

Mongolia

Montenegro

Morocco

Mozambique

Namibia

Nepal

Nicaragua

Niger

Nigeria

Oman

Pakistan

Palau

Panama

Papua New Guinea

Paraguay

Peru

Philippines

Poland

Qatar

Romania

Russia

Rwanda

Saint Kitts and Nevis

Saint Lucia

Saint Vincent and the Grenadines

Samoa

São Tomé and Príncipe

Saudi Arabia

Senegal

Serbia

Seychelles

Sierra Leone

Solomon Islands

Somalia

South Africa

South Sudan

Sri Lanka

Sudan

Suriname

Swaziland

Syria

Tajikistan

Tanzania

Thailand

Timor-Leste

Togo

Tonga

Trinidad and Tobago

Tunisia

Turkey

Turkmenistan

Tuvalu

Uganda

Ukraine

United Arab Emirates

Uruguay

Uzbekistan

Vanuatu

Venezuela

Vietnam

Yemen

Zambia

Zimbabwe

Cuba

Nauru

North Korea

Indonesia

Jakarta

denpsar,AFGANISTAN,IRAN,POLAND,MALASIYA

1. The products of IB-Series have smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark. The machine is most suitable for manufacturing high quality products.

2. The mold design adopts the method of common mold base. Only by changing the mold parts, the product's shape, weight, or even the length can be changed. It saves time on mold alignment and doesn't require great expertise on mold changeover. Thus, it reduces the mold cost on manufacturing a wide range, but low volume of different applications.

3. The mechanical design is based on the blueprint of general-purpose injection molding machine. Hence, with general knowledge of injection molding machine, no matter machine operation or maintenance work can be handled with ease.

4. Applied materials include PC, PP, PE, PS, AS, PMMA, K-Resin, PET, PETG, TPR, PES, PCO and NYLON.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!