2017 High quality Nanrong 250t used Injection Molding Machine to Iraq Factory

2017 High quality Nanrong 250t used Injection Molding Machine to Iraq Factory Detail:

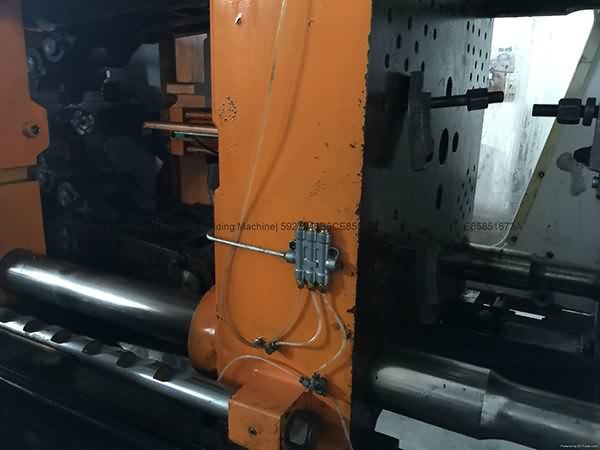

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

Our primary intention should be to offer our clientele a serious and responsible enterprise relationship, delivering personalized attention to all of them for 2017 High quality Nanrong 250t used Injection Molding Machine to Iraq Factory, The product will supply to all over the world, such as: Canada , Armenia , UK , With more and more Chinese products and solutions around the world, our international business is developing rapidly and economic indicators big increase year by year. We have enough confidence to supply you both better solutions and service, because we've been more and more powerful, specialist and experience in domestic and international.

20L Pail Forza PT450H Production Dry cycle

Máy ép nhựa Forza 450T ép thùng 20L (máy chạy không tải), với hệ thống dán nhãn bên trong IML, làm cho chu kỳ sản xuất ngắn hơn.

Liên hệ: 0909 725 216

Matt Pearce beats Mould for the first time and claims the Northern Masters.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!