2017 Latest Design CLF-200TY used Injection Molding Machines to The Swiss Manufacturers

2017 Latest Design CLF-200TY used Injection Molding Machines to The Swiss Manufacturers Detail:

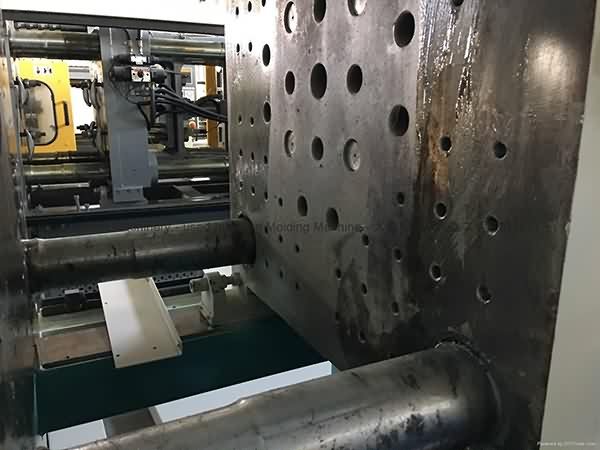

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for 2017 Latest Design CLF-200TY used Injection Molding Machines to The Swiss Manufacturers, The product will supply to all over the world, such as: New Zealand , Slovakia , Lithuania , Faced with the vitality of the global wave of economic integration, we've been confident with our high-quality items and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

027-87514692/武汉丽晶电子/744271986@qq.com/LMG5278XUFC-00T,Hitachi 9.4inch Injection molding machine LCD Panel; More models LCD panel, please ...

Plastic scrap - Briquette press machine test.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.