2017 Latest Design Haitian 120t used Injection Molding Machine to Johor Importers

2017 Latest Design Haitian 120t used Injection Molding Machine to Johor Importers Detail:

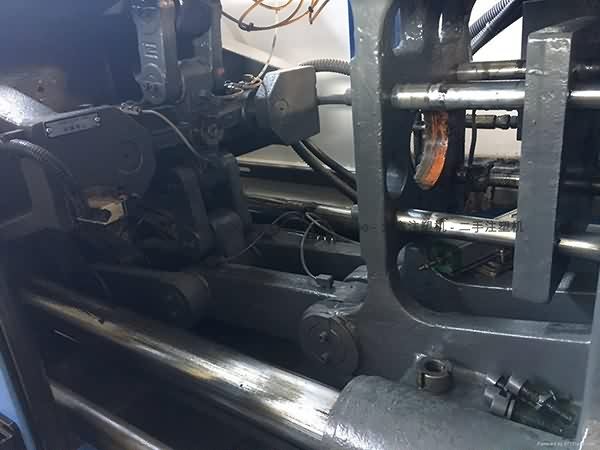

Haitian 120t used Injection Molding Machine

Model: SA1200/370.

Year: 2010.

Screw: A-D34.

Tie bar spacing: 410mm.

Two units. Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for 2017 Latest Design Haitian 120t used Injection Molding Machine to Johor Importers, The product will supply to all over the world, such as: Russia , Cologne , Bangkok , Our focus on product quality, innovation, technology and customer service has made us one of undisputed leaders worldwide in the field. Bearing the concept of "Quality First, Customer Paramount, Sincerity and Innovation" in our mind, We have achieved great progress in the past years. Clients are welcomed to buy our standard products, or send us requests. You will be impressed by our quality and price. Please contact us now!

WEBSITE: hoyofootwear.en.alibaba.com EMAIL:hoyofootwear@163.com.

CINCINNATI MILACRON 220-TON PLASTIC INJECTION MOLDING MACHINE, MODEL VT-220-20, 17 OZ (482 GRAMS), 1990, CAMAC XTL CONTROLS, 21.3" ...

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!