2017 Latest Design Haitian 380t used Injection Molding Machine to India Factories

2017 Latest Design Haitian 380t used Injection Molding Machine to India Factories Detail:

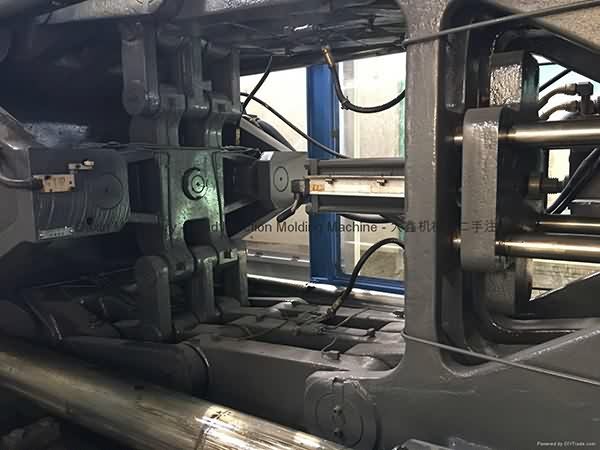

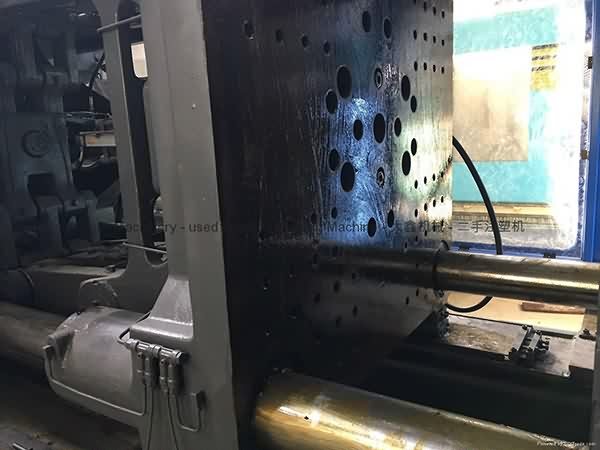

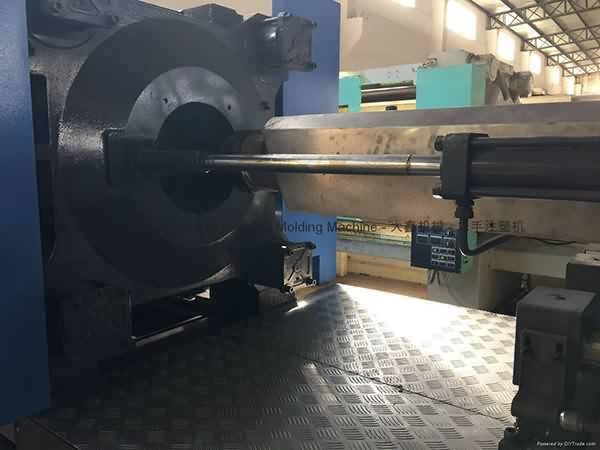

Haitian 380t used injection molding machine .

Model: SA3800/2250v.

Year : 2010.

Screw type: B-D70.

Tie bar spacing: 720x720mm

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for 2017 Latest Design Haitian 380t used Injection Molding Machine to India Factories, The product will supply to all over the world, such as: Casablanca , moldova , Pakistan , Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

Call: 888-803-3412 Used Plastic Machinery For Sale In Pakistan From Plastic Machinery & Parts Searching for used plastic machinery for sale in Pakistan?

ukázka rychlosti plně elektrického stroje JSW verze J-110AD A jak rychle běhá Váš vstřikolis ?

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.