2017 Latest Design JSWJ1300EIII used Injection Molding Machine to Iraq Factories

2017 Latest Design JSWJ1300EIII used Injection Molding Machine to Iraq Factories Detail:

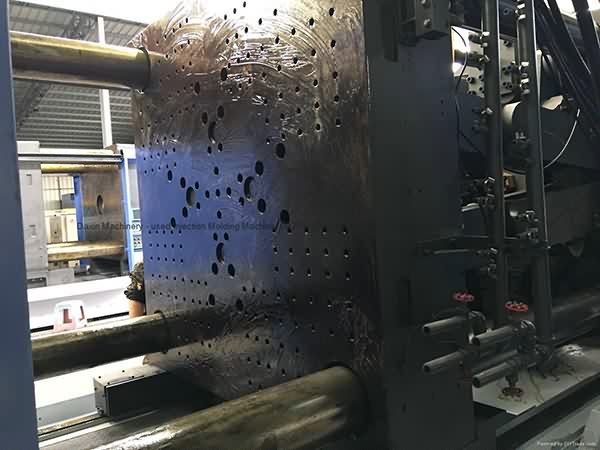

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Our pursuit and company intention is usually to "Always fulfill our purchaser requirements". We go on to acquire and layout excellent high quality products for both our previous and new consumers and realize a win-win prospect for our customers too as us for 2017 Latest Design JSWJ1300EIII used Injection Molding Machine to Iraq Factories, The product will supply to all over the world, such as: Finland , Surabaya , Canada , With the growing of the company, now our products sold and served at more than 15 countries around the world,such as Europe,North America,Middle-east,South America,Southern Asia and so on. As we bear in our mind that innovation is essential to our growth, new product development is constantly.Besides, Our flexible and efficient operation strategies,High quality products and competitive prices are exactly what our customers are looking for. Also a considerable service brings us good credit reputation.

TCM BALER:https://www.tcmbaler.com/ a professional manufacturer, specialize in hydraulic compressing machine/ baling press compactor/pressing baler for more than 15years, Our products are applicable for waste cardboard/ cardbox, OCC, plastic bottles ,fiber, rags,wipers,used clothes/clothing,textiles, cotton, newspaper, kraft paper, scrap metal, mattress spring, scrap car body, heavy steel etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.Fully automatic horizontal baling press

2.Semi-automatic horizontal baling press

3.vertical baling press baler

4.wipers/rags bagging press baler

5.scrap metal baling compactor

6.shearing baler machine

7.container shear

8.movable scrap metal baler compactor

9.single shaft shredder

10.double shaft shredder

https://www.tcmbaler.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: info@tcmbaler.com

Wood Shaving Baler, Wood Shavings Baler Austria, automated silage packer, Wood Shaving Baler Sinobaler Wood Shavings Baler Wood Chip Baling Press. Wood shaving and wood chips are usually above 1 to cm in size. Compared to, silage baler machine price baling corn silage, Baler For Wood Shavings wooden Shavings Finland, silage hydraulic press machine cron silage baler, Baler For Wood Shavings wooden Shavings Baling Machine wood Chip Baler Machine, Find Complete Details about Baler For Wood Shavings wooden Shavings Baling Machine, wood chipper bailing press, wood shaves baler wood chips baler, wood Fiji, silage pressing 2017 in pakistan, wood shaves baler wood chips baler, Small Horizontal hay baler for wood shavings, straw, rice husk, scrap clothing, waste paper. Features:, silage in poly bags baler silage press, Wood Chips Baler, Wood Chips Baler Micronesia, wood shaving baler machine fast, Wood Chips Baler, Wholesale Various Hydraulic Baler For Wood Shavings Wood Sawdust wood chip Baler Machine. Ad. US $2000 20000 Set . 1 Unit Min. Order, silage box bags packing machine simple, wood shavings compress machine of France, chinese corn silage bailer hydraulic press for silage grass, Quality wood shavings compress machine find quality Hydraulic Baler Machine, Balers Hydraulic Baler Machine from Zhengzhou Yamei Machinery Manufacturing Co., Ltd, small square silage corn silage baler machine for sale in india, China Supplier Wood Shavings Baler China India, bagging cotton seed husk cottonseed hull, China Supplier Wood Shavings Baler, Find details about China Baler, Wood Shaving Baler from China Supplier Wood Shavings Baler Zhengzhou Leabon Machinery, cut silage bale wrap corn silage balers for sale, Wood Shavings Baler RMGroup Kuwait, wooden mini bailer enerpat wood shaving, Wood shavings baling machines for sale UK, Wood Chips bagging and baler equipment, machines and systems from RMGroup Uk, how to compress wood shavings sawdust bales, Balers for wood shavings and sawdust, ESSEGI Luxembourg, how to compact rice shell coconut husk bundling machine, ESSEGI provides fully automatic or semi automatic balers to pack wood shavings and sawdust into 1 kg to 25 kg squared Automatic Horizontal baler for 20 25 kg 4, sawdust baler enerpat compressing wood chips, Wood Shavings Baler, Chips Baling Machine Latvia, mini silage bagger silage vacuum packing, This baler is devoted to disposal of wood shavings and chips. It compresses small sized grain materials. Wood chips can be used to make particleboards, sawdust boards., homemade hydraulic sawdust briquette press, Wood Shavings Baler Bagger Press Monaco, bagging system for sawdust press wood shavings, Daytech Wood Shaving baler Bagger Press Daytech design and build these machines to suit customers requirements. The daytech wood shavings press in, seal plastics packaging for wood shaving press baler, Wood Shaving Baler manufacturers Netherlands China Wood Shaving Baler manufacturers Select 2017 high quality Wood Shaving Baler products in best price from certified Chinese Wood Parts manufacturers, Wood Line Baling Press, Wood Shavings Baler, HuiCheng Nauru This bale press is designed for baling loose and small material, such as wood shavings, rice husks, sawdust, peanut shells. This baler is applied for animal feed and Used Wood Shavings Sawdust Compress NiueChina Used Wood Shavings Sawdust Compress Baler Machine, Find details about China Wood Shavings Baler Machine, Wood Shavings Baler from Used Wood Shavings WOOD SHAVING WOOD CHIPS BALING New Zealand This machine is mainly used to compress wood dust, wood chips, rags, rice husk, flour, pulp, leaves, drug, this horizontal bagging baler is ideal for pet food Good performance sawdust wood shavings Puerto Rico Good performance sawdust

In this video there is a introduce of the plastic molding and CAE technology`s development. C-mold for plastic mold simulation analysis software was the best one but annexed because a mistake made by an engineer.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.