2017 Latest Design Sumitomo 130t All-Electric used Injection Molding Machine Export to Angola

2017 Latest Design Sumitomo 130t All-Electric used Injection Molding Machine Export to Angola Detail:

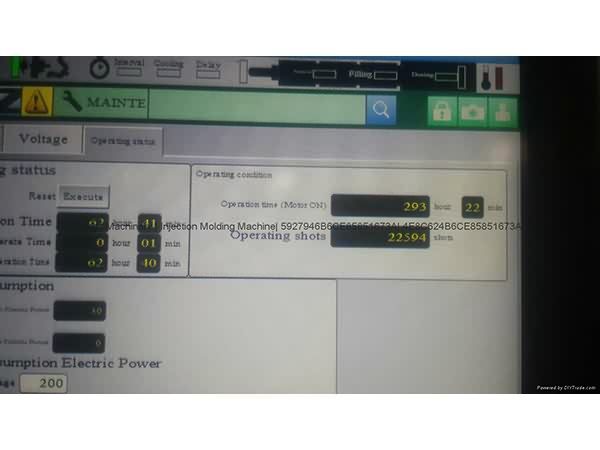

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for 2017 Latest Design Sumitomo 130t All-Electric used Injection Molding Machine Export to Angola, The product will supply to all over the world, such as: Los Angeles , Chile , Paris , Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

PET Preform Injection Machine FROM China Evertopmachine

https://www.evertopmachine.com/

https://www.evertopmachine.com/water-filling-machine/

https://www.evertopmachine.com/carbonated-beverage-filling-machine/

https://www.evertopmachine.com/juice-tea-hot-filling-machine/

https://www.evertopmachine.com/barreled-drink-water-filling-machine/

https://www.evertopmachine.com/glass-bottle-filling-machine/

https://www.evertopmachine.com/can-filling-machine/

https://www.evertopmachine.com/oil-filling-machine/

https://www.evertopmachine.com/milk-filling-machine/

https://www.evertopmachine.com/wine-filling-machine/

https://www.evertopmachine.com/labeling-machine/

https://www.evertopmachine.com/water-treatment-system/

https://www.evertopmachine.com/blow-moulding-machine/

https://www.evertopmachine.com/injection-moulding-machine/

https://www.evertopmachine.com/automatic-bottle-packing-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-bottling-machine/

https://www.evertopmachine.com/other-ancillary-packing-machinery/

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!