2017 Latest Design Toshiba IS650GT Used Injection Molding Machine Supply to Jamaica

2017 Latest Design Toshiba IS650GT Used Injection Molding Machine Supply to Jamaica Detail:

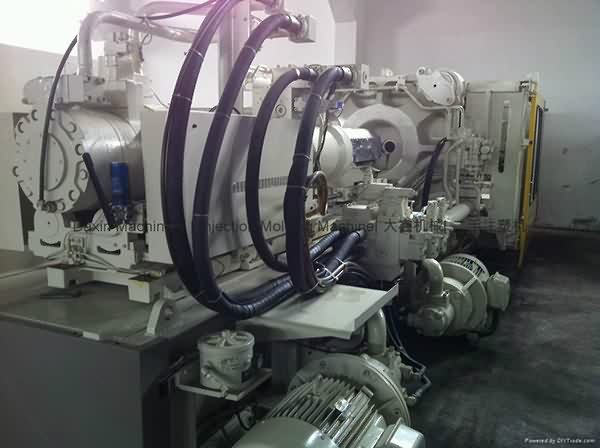

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for 2017 Latest Design Toshiba IS650GT Used Injection Molding Machine Supply to Jamaica, The product will supply to all over the world, such as: Armenia , Kuwait , Estonia , The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

Mould steel: P20 core and cavity

Hardness: 40 HRC

Machine: 1000 ton

Visit https://www.usedmoldmarket.com/

I am lily from China Darin Machinry. If you are interested our machine. Please do not hesitate to contact me at any time.

Looking forward to your inquiry.

Lily

JINAN DARIN MACHINERY CO., LTD

Skype:darinlilyliu

QQ: 103386119

Wechat:smile520lily

Whatsapp/Viber/Mobile: 0086 15063392887

E-mail: darin10@darin.cn

Facebook:liulili_7981530@126.com

Web: www.darin.cn or www.packingmachine.org

Pet Treats Injection Moulding Machine is special machinery for producing pet snacks. With such machine, various shapes can be made, such as hedgehog, crocodile, dog, bone, pork ears, barrel, etc. The shapes are very lovely and it is a ideal encouragement to dogs and cats while they learn a new action or do well in some exercises and games. Also, we can provide different recipes to meet various market demands.

1.Pet Treats Injection Moulding Machine comes with user-friendly microprocessor controller with these following features.

2.Equipped with servo motor to realize higher efficiency and lower consumption.

3.Dust, oil proof and colorful touch switch control panel.

4.El display of pressure, speed, time and distance for each motion.

5.Shut-down device with 100 presets mold data memory.

6.Equipped with 4 stages injection, 3 stages holding pressure and 3 stages back pressure.

7.PID barrel temperature control: temperature abnormal & electrical wire disconnection alarm.

8.SSR-solid state temperature controller.

9.Screw cold start protection.

10.Abnormal shot detection.

11.Output quantity and packaging quantity preset.

12.Clamping, injection and ejection (option), and carriage action (option) by linear potentiometer.

13.Screw rotating speed read-out.

14.Security code function to avoid missing data or careless changing.

15.Super low pressure clamping ensures security of user, and maintains lifespan of machine efficiently.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!