2017 New Style Chuan Lih Fa CLF-950TX used Injection Molding Machine to Istanbul Factory

2017 New Style Chuan Lih Fa CLF-950TX used Injection Molding Machine to Istanbul Factory Detail:

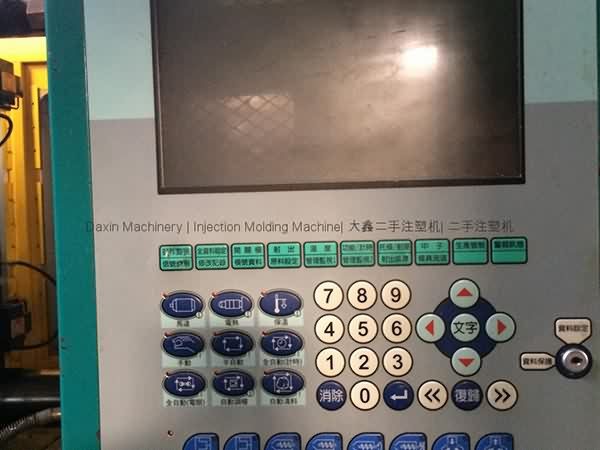

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

We consistently execute our spirit of ''Innovation bringing progress, Highly-quality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for 2017 New Style Chuan Lih Fa CLF-950TX used Injection Molding Machine to Istanbul Factory, The product will supply to all over the world, such as: Sevilla , Liverpool , United Arab emirates , Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

Fordern Sie bei Logismarket weitere Informationen an: https://www.logismarket.ch/storopack/schaumpolstermaschine/1428512601-699516362-p.html Foamplus ...

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034828?

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.