2017 New Style CLF-200TY used Injection Molding Machines for Egypt Manufacturer

2017 New Style CLF-200TY used Injection Molding Machines for Egypt Manufacturer Detail:

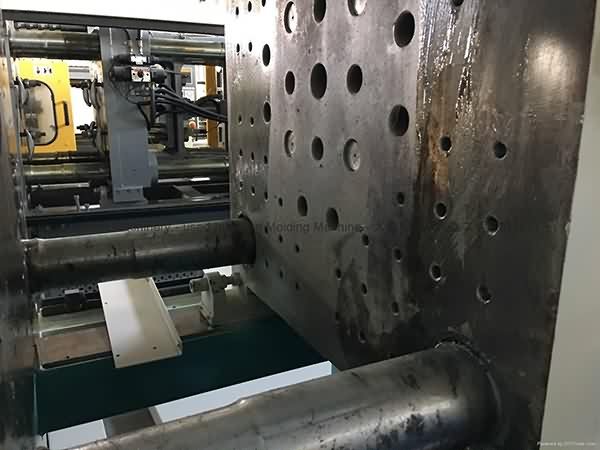

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

We always believe that one's character decides products' quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for 2017 New Style CLF-200TY used Injection Molding Machines for Egypt Manufacturer, The product will supply to all over the world, such as: Tanzania , Gambia , Salt Lake City , Our products are widely sold to Europe, USA, Russia, UK, France, Australia, Middle East, South America, Africa, and Southeast Asia, etc. Our products are highly recognized by our customers from all around the world. And our company is committed to continually improving effectiveness of our management system to maximize customer satisfaction. We sincerely hope to make progress with our customers and create a win-win future together. Welcome to join us for business!

Roll forming line for production of Car frame elements

Pay attention: guards and safety barriers have been removed for viewing.

All dispositive must be in place for safe operation

Jet Engine Automation Co., Ltd. www.jetrobot.com.tw.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.