8 Year Exporter Chen Hsong Super Master SM250TS used Injection Molding Machine for Lahore Manufacturers

8 Year Exporter Chen Hsong Super Master SM250TS used Injection Molding Machine for Lahore Manufacturers Detail:

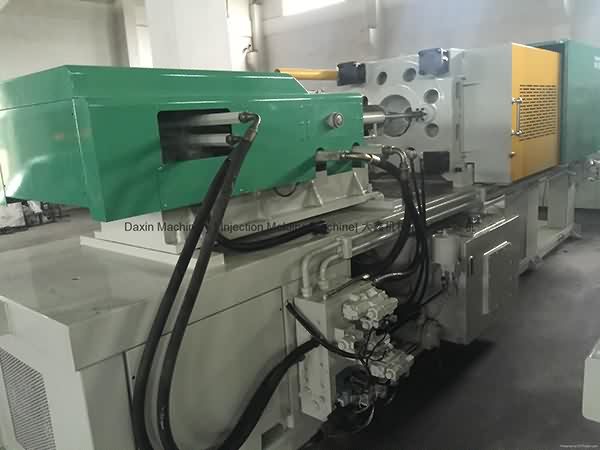

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

Fast and superior quotations, informed advisers to help you choose the correct merchandise that suits all your requirements, a short generation time, responsible quality control and different services for paying and shipping affairs for 8 Year Exporter Chen Hsong Super Master SM250TS used Injection Molding Machine for Lahore Manufacturers, The product will supply to all over the world, such as: Bandung , Liverpool , Singapore , Many products fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't need to waste time shopping around.

SOGUTECH.COM

www.enjeksiyondaikinciel.com Gsm: 0532 251 02 98.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.