8 Year Exporter Haitian 1300t (servo) used Injection Molding Machine – CLF Used Plastic Machinery

8 Year Exporter Haitian 1300t (servo) used Injection Molding Machine – CLF Used Plastic Machinery Detail:

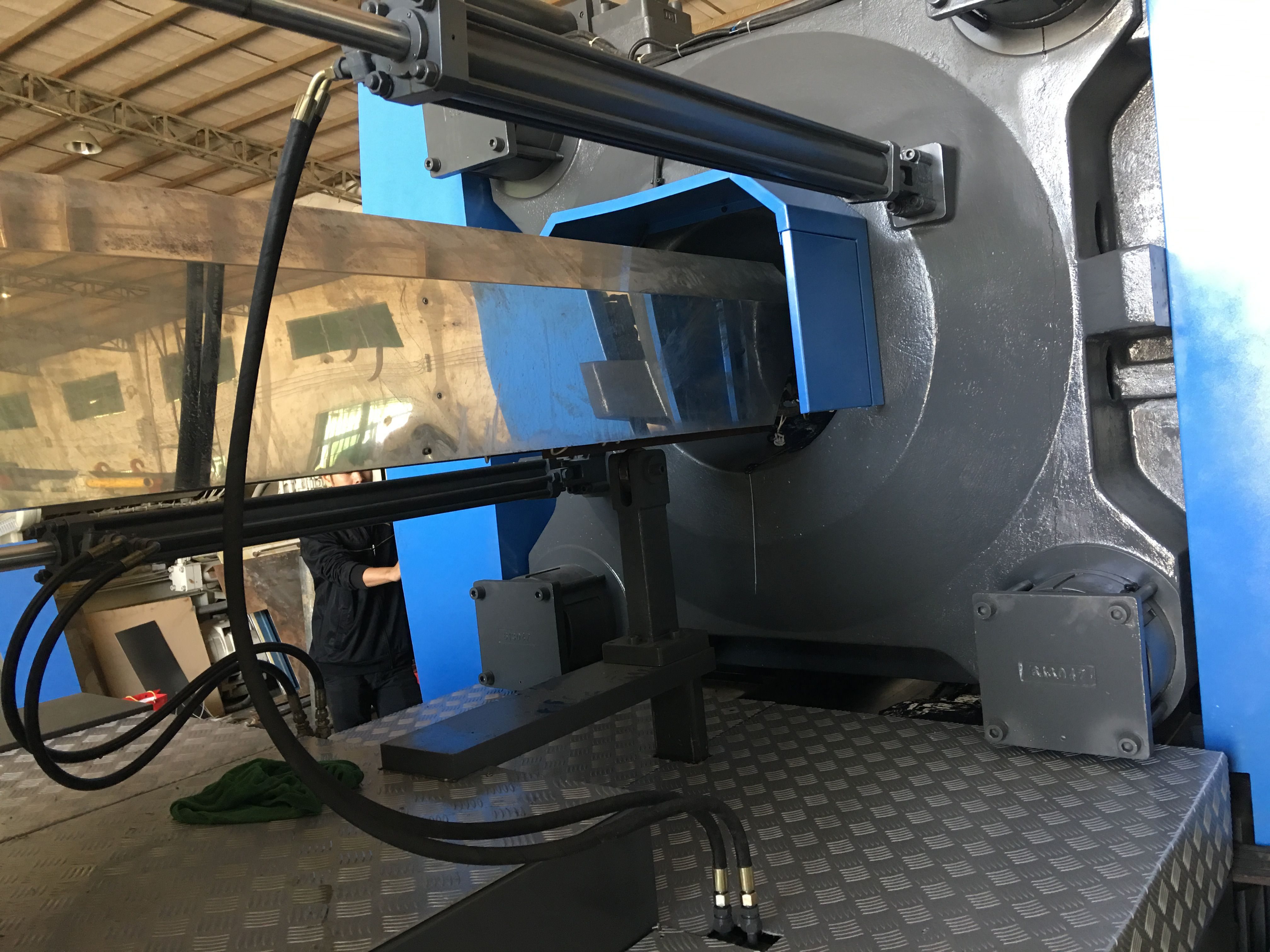

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

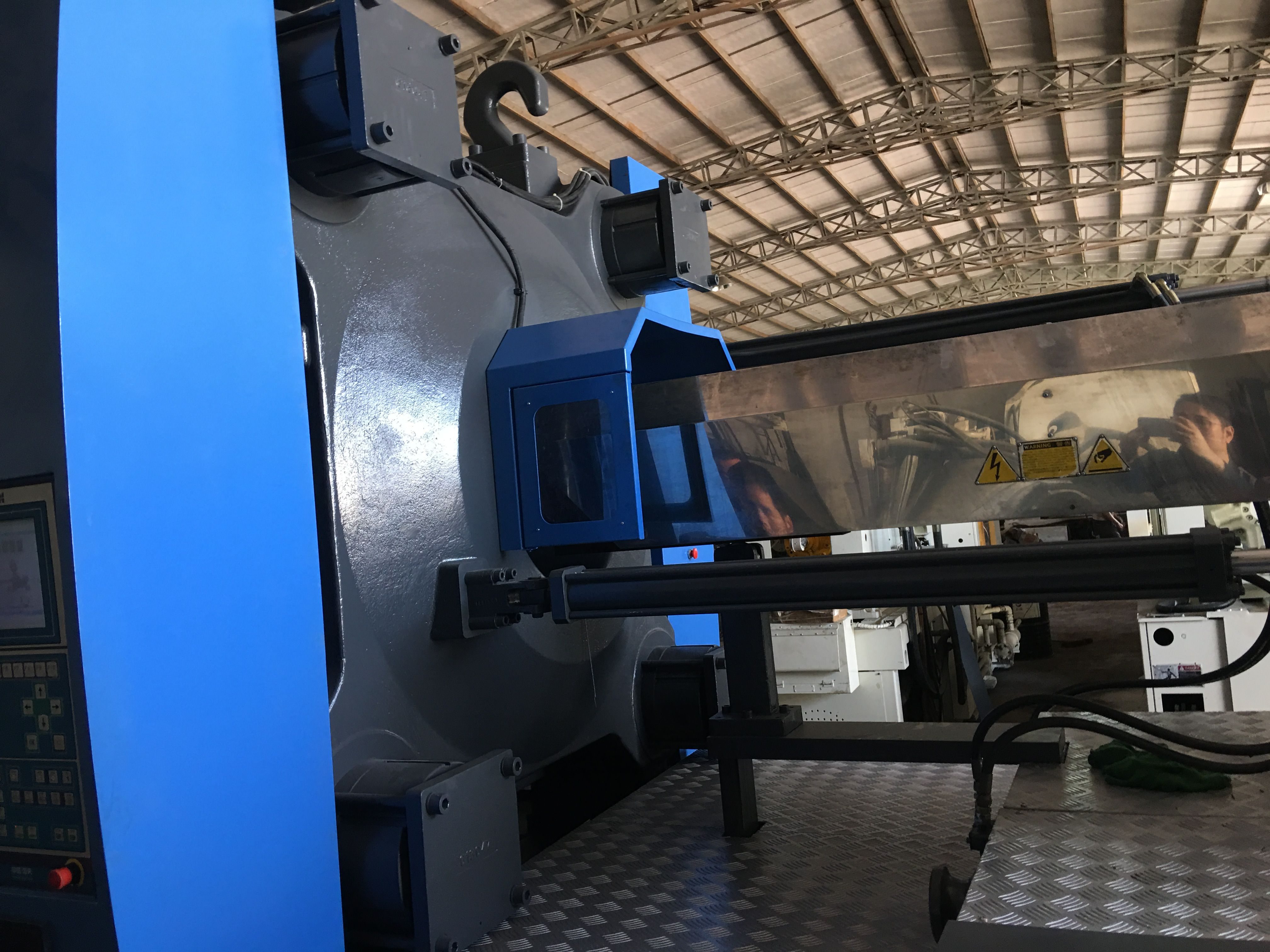

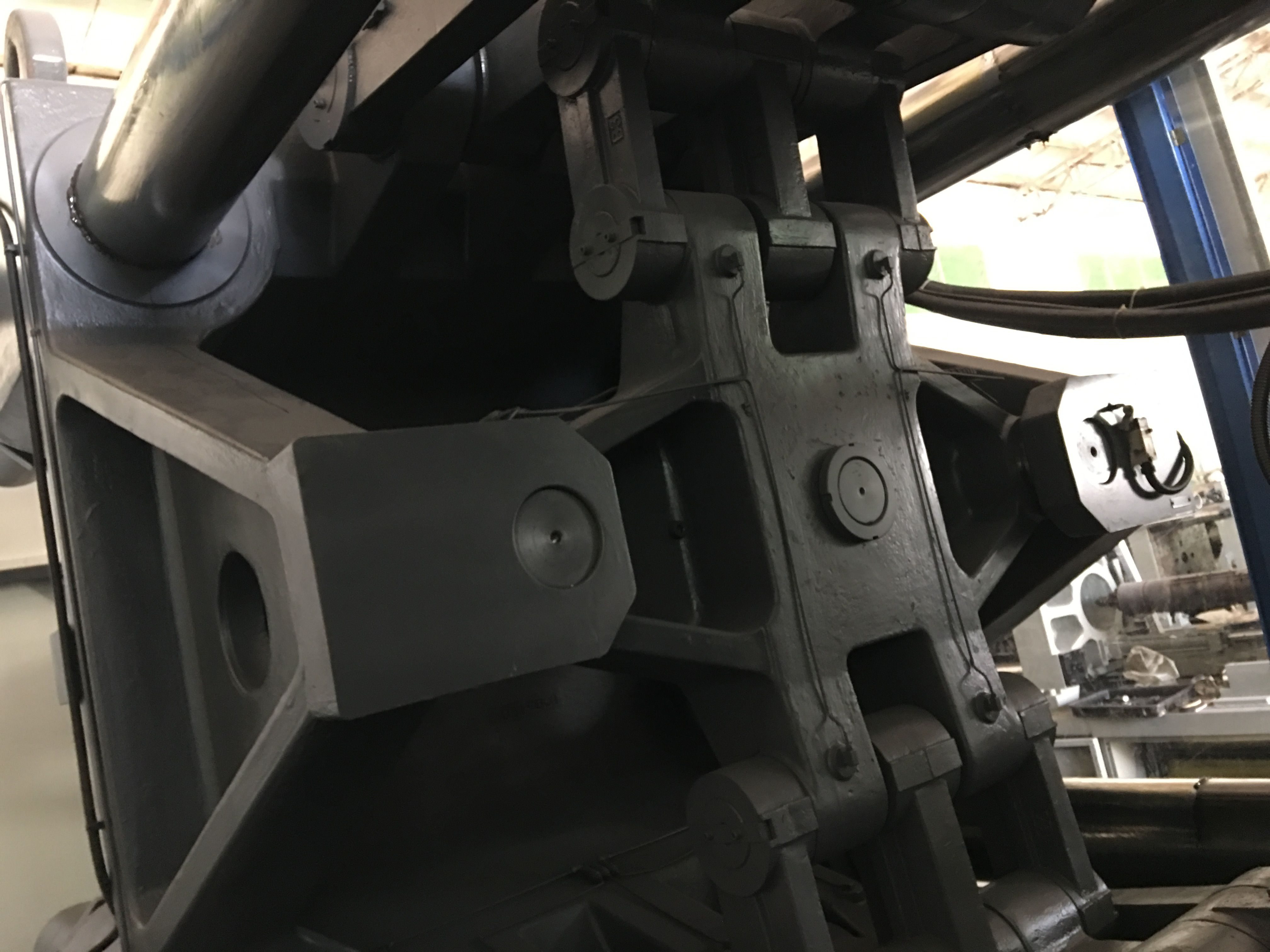

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for 8 Year Exporter Haitian 1300t (servo) used Injection Molding Machine – CLF Used Plastic Machinery, The product will supply to all over the world, such as: Puerto Rico , Mexico , Auckland , Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

www.borum.as

Ultra Linemarking from Autralia have purchased their first Borum second hand machine in 2016.

The BM 250-2 is supplied with the Borum thermoplastic extruder for applying flat and profiled markings.

See what second hand machines we have available on www.borum.as or https://goo.gl/W1qsi0

Contact: Ms Linda Liu

MP:+86-18865650128

Email:gbllinda@hotmail.com

SKYPE: linda-82132006

QQ: 20579250

https://www.foam-container-machine.com

PS foam sheet extruder machine/PS foam sheet plastic extruder

PS/EPS fully auto forming and cutting machine can form PS/EPS foam box, tray, plate, container, egg box etc. by changing moulds. We will design mould according to your sample and requirements, and can also put your company LOGO on the mould. It is fully automatic. Forming, cutting and stacking are done in the same machine.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.