8 Year Exporter Haitian 200t (servo) used Injection Molding Machine to South Africa Factories

8 Year Exporter Haitian 200t (servo) used Injection Molding Machine to South Africa Factories Detail:

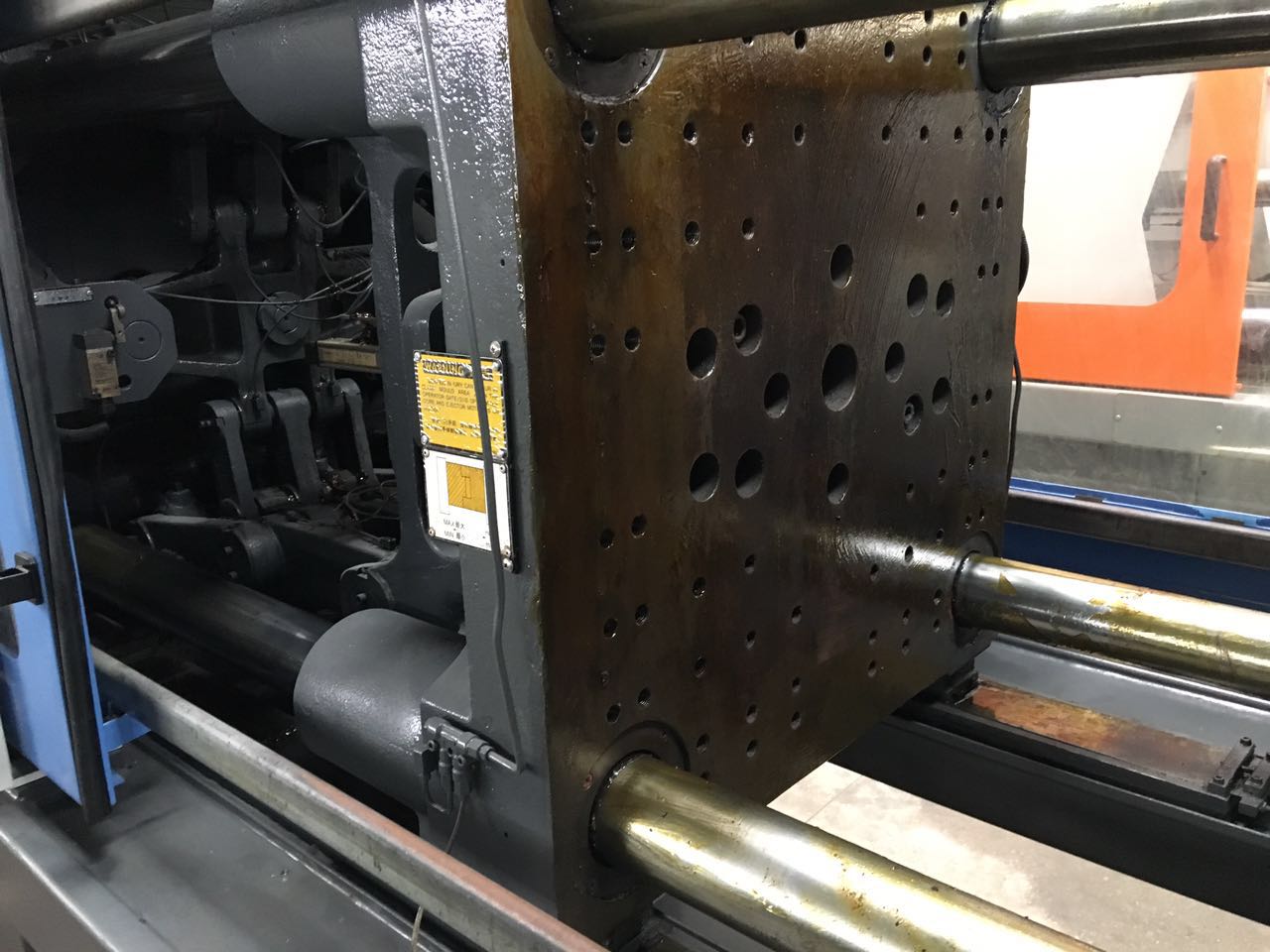

Haitian 200t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

With reliable quality process, good reputation and perfect customer service, the series of products produced by our company are exported to many countries and regions for 8 Year Exporter Haitian 200t (servo) used Injection Molding Machine to South Africa Factories, The product will supply to all over the world, such as: Saudi Arabia , New York , Iraq , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

At EuroMold 2014 Stratasys presented a host of game-changing 3D printed manufacturing applications including composite processing tooling, jigs and fixtures, ...

A quick into to GS-5T Molding Press Contact us by email: viasales@viabiomedical.com by phone: 763-577-9936 or online: viabiomedical.com.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.