8 Year Exporter Toshiba IS650GT Used Injection Molding Machine for The Swiss Manufacturers

8 Year Exporter Toshiba IS650GT Used Injection Molding Machine for The Swiss Manufacturers Detail:

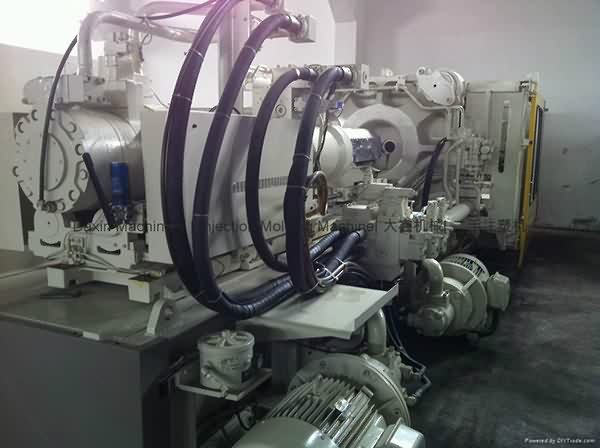

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We believe in: Innovation is our soul and spirit. High-quality is our life. Purchaser need is our God for 8 Year Exporter Toshiba IS650GT Used Injection Molding Machine for The Swiss Manufacturers, The product will supply to all over the world, such as: Monaco , Slovenia , Guatemala , We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

EPS machine for lost foam casting of cushioning device cases/ Автомат для моделей корпуса поглощающего аппарата

email :petro.s.cherednichenko@gmail.com, website: smm-engineering.com.

More information & Pictures: https://www.evermak.com/ITEM.PRO?S=5594&_setlang=EN

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!