Best Price for Chuan Lih Fa CLF-950TX used Injection Molding Machine for Norwegian Factory

Best Price for Chuan Lih Fa CLF-950TX used Injection Molding Machine for Norwegian Factory Detail:

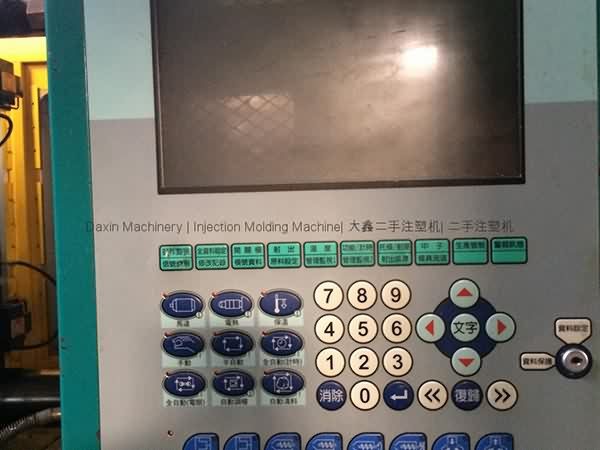

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Best Price for Chuan Lih Fa CLF-950TX used Injection Molding Machine for Norwegian Factory, The product will supply to all over the world, such as: UAE , Malawi , Bolivia , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

how to manufacture the PVC electrical fitting through Injector Machine

Please subscribe my channel for more videos.

Roads and engineering stuff.

-~-~~-~~~-~~-~-

Please watch: "folding houses"

-~-~~-~~~-~~-~-

25 Ton Boy Injection Molding Machine, Model 25D, 1998 Vintage.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.