Best Price on Niigata 180t used All-electric Injection Molding Machine to Greenland Factories

Best Price on Niigata 180t used All-electric Injection Molding Machine to Greenland Factories Detail:

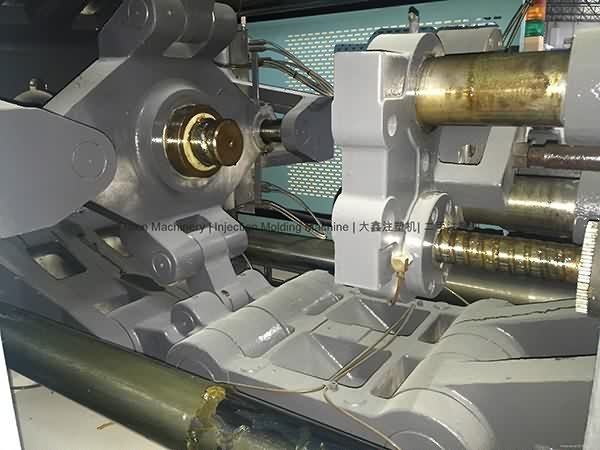

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

Using a total scientific good quality management process, superior high quality and excellent faith, we get great name and occupied this field for Best Price on Niigata 180t used All-electric Injection Molding Machine to Greenland Factories, The product will supply to all over the world, such as: Oslo , Greenland , St. Petersburg , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

Disney Collector brings you Play-Doh Peppa Pig stampers with Daddy pig, Mummy pig, Peppa pig and George pig stamps. In this video I'm also using the Talking Car Picnic Adventure.

Music from Kevin Macleod.

Disney Frozen Magic Color Changers Anna Coronation Dress.

Disney Frozen Anna Elsa Sleepover at Barbie Glam House.

Princess Sofia Royal Prep Academy Magical Talking Castle.

Play-Doh Meal Makin' Kitchen Princess Sofia the First.

Frozen Magiclip Glitter Glider Anna Elsa Olaf Magic Clip.

Glitter Glider Castle Set Disney Princess Magic Clip Dolls.

Glitter-Glider Dolls Magic clip Belle Rapunzel Elsa Anna.

Disney Frozen Dress-Up Magnetic Wooden Wardrobe Magnets.

Ariel Floating Fountain Color Changers Mermaid Sisters.

Disney Frozen Royal Closet Anna Elsa & Barbie Carry Case.

Play-doh Sofia the First Royal Tea Party w/ Doc McStuffins:

Disney Frozen Ice Skating Elsa & Ice Skating Princess Anna.

Princess Ariel Rapunzel Slumber Party Sleepover at Barbie.

New Sofia The First Royal Tea Party Picnic Doll 40 Phrases!

NEW Play-Doh Sofia the First Amulet Jewels Vanity Sparkle.

Sleeping Beauty Princess Aurora Color Changing Magic Dress.

https://www.youtube.com/user/DisneyCollectorBR/videos

Play-Doh Disney Princess Belle Royal Tea Party playdough.

https://www.youtube.com/user/DisneyCollectorBR/videos

Disney Princess Cinderella Royal Tea Party Time Belle.

https://www.youtube.com/user/DisneyCollectorBR/videos .

.

Check out reviews from Toycollector Blucollection at:

https://www.youtube.com/user/Blucollection .

Click to Subscribe DCTC Toys-Collector Unboxing Channel:

https://www.youtube.com/DCtoysCollector

Assista ao Canal Brasileiro de Brinquedos e Bonecas.

https://www.youtube.com/BrinquedoseBonecas

Information about the Dorman Fuel Line Repair Kit, part number 800-300.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!