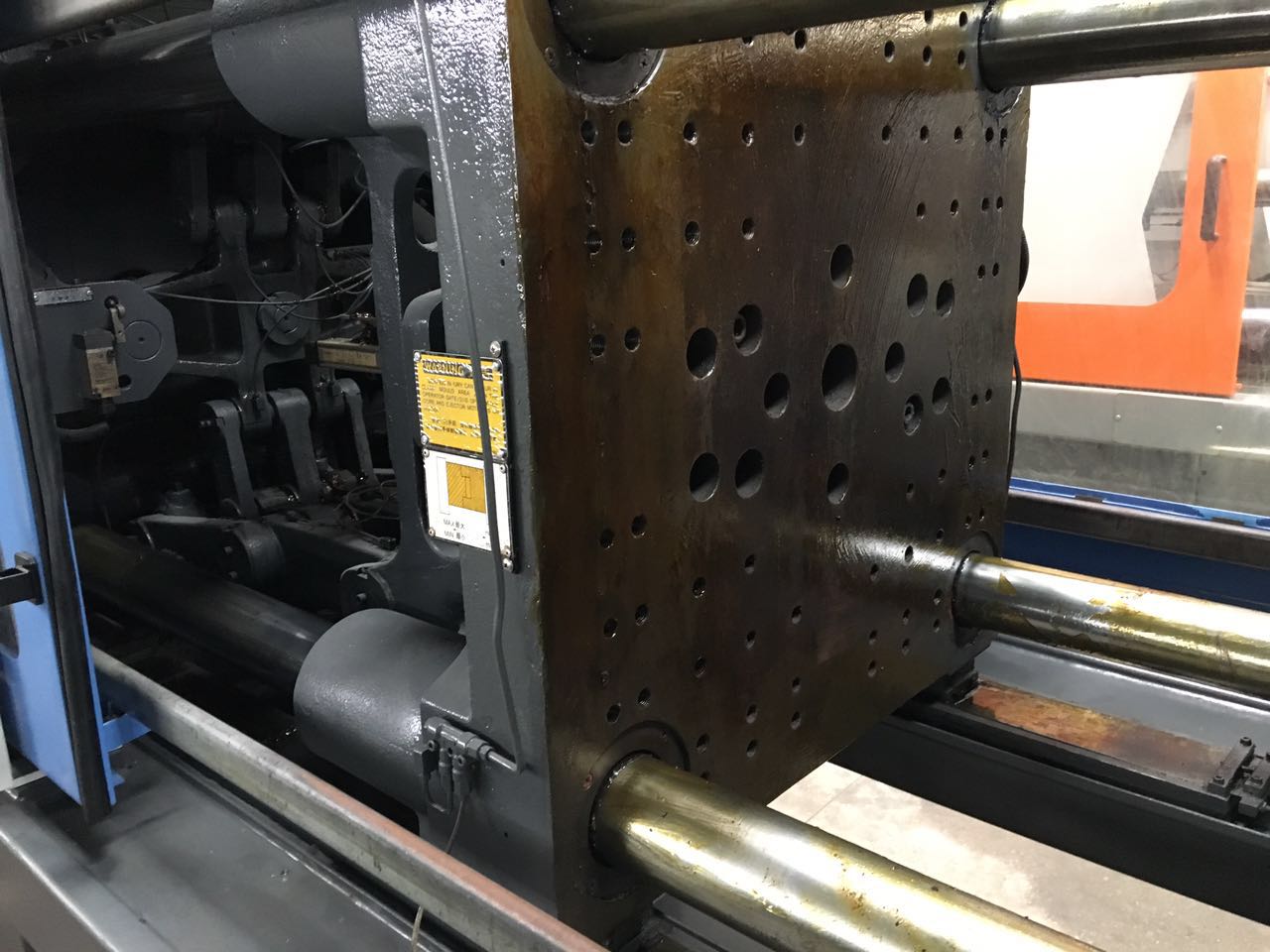

Best quality Haitian 200t (servo) used Injection Molding Machine Export to Argentina

Best quality Haitian 200t (servo) used Injection Molding Machine Export to Argentina Detail:

Haitian 200t (servo) used Injection Molding Machine

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Best quality Haitian 200t (servo) used Injection Molding Machine Export to Argentina, The product will supply to all over the world, such as: Nigeria , Seattle , Cairo , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

China Pipe bending machine supplier

NBM38R2-4A Auto Chair OD12.5mm pipe bending machine

4 Axis with Yaskawa servo motor, Spinea reduction box,Dynapath PC , Simens hydraulic system, multiply stacks tooling

NABOK serise machine features:

Using industrial touch screen, with the simple operation interface in English; high precision, high degree of automation and multifunctional; each action of machine is controlled by PLC programme control system or the IPC (Industrial Personal Computer).

1. Fully automatic and CNC pipe bending machine

2. Equipped with 4 servomotor programmable axis, 4 axis, 5 axis or 6 axis.

3. Feeding: servomotor drive; Rotation: servomotor drive

4. Bending: hydraulic and encoder control; Servomotor with reducer.

5. Imported hydraulic system and PLC unit or IPC.

6. Automatic lubrication system for moving areas

7. Self-diagnostic system, detecting the error immediately

8. Multiple groups pipe-bending information storage

9. Electric cabinet cooling fan/aircondition and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature

10. Touch screen and human/machine interface control provide user friendly operations.

NABOK Machinery have great pipe and wire processing equipments from China (tube bending, end forming and cutting machines), with decent quality and suitable price.

Website: www.NABOK.com.cn /www.tubebender.com.cn .

Contact person: Mr Andy Qian

Email: nabokmachines@hotmail.com

Cell:86-18001561868

Tube bending machine supplier from China- NABOK Machinery

Our Advantage: high quality ,intimate service , reasonable price

Forming our future with you !

China tube bending machine supplier

During the 1980's the plastic making industry in Taiwan began to take off with many companies subcontracting their operations to Taiwanese suppliers. Through ...

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!