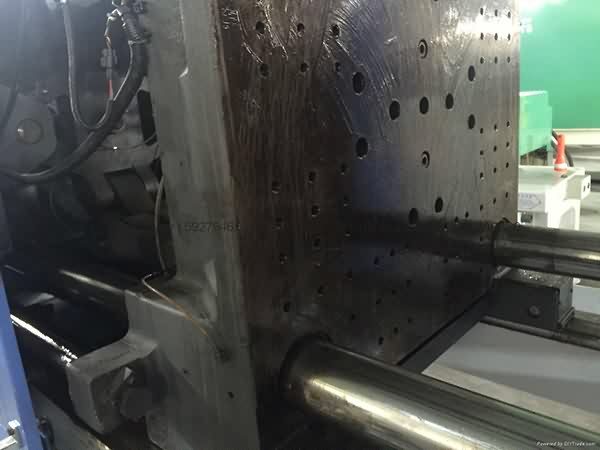

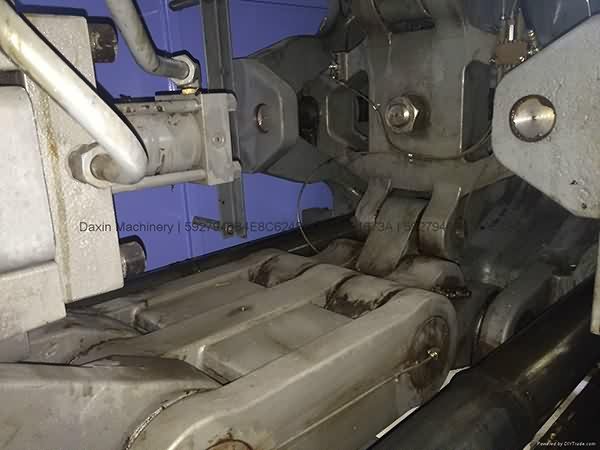

Best quality JSWJ280EIII used Injection Molding Machine to Malawi Factory

Best quality JSWJ280EIII used Injection Molding Machine to Malawi Factory Detail:

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

That has a sound small business credit, great after-sales service and modern production facilities, we've earned an outstanding standing amid our buyers across the earth for Best quality JSWJ280EIII used Injection Molding Machine to Malawi Factory, The product will supply to all over the world, such as: Yemen , Bulgaria , Cyprus , We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

Giken Sakata (S) Limited - Japanese

027-87514692/武汉丽晶电子/744271986@qq.com/LMG5278XUFC-00T,Hitachi 9.4inch Injection molding machine LCD Panel; More models LCD panel, please ...

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!