Best quality Niigata 180t used All-electric Injection Molding Machine Wholesale to Ecuador

Best quality Niigata 180t used All-electric Injection Molding Machine Wholesale to Ecuador Detail:

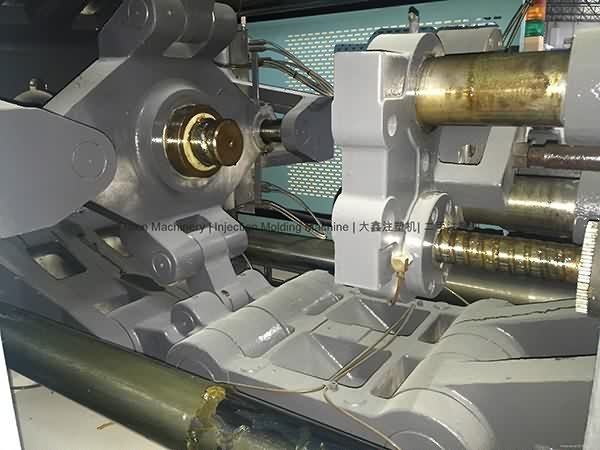

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Best quality Niigata 180t used All-electric Injection Molding Machine Wholesale to Ecuador, The product will supply to all over the world, such as: French , The Swiss , Honduras , Our aim is to help customers to make more profits and realize their goals. Through a lot of hard work, we establish a long-term business relationship with so many customers all around the world, and achieve win-win success. We will continue to do our best effort to service and satisfy you! Sincerely welcome you to join us!

Gia cong ép nhựa giá rẻ toàn quốc số lượng ít 100- 1000 Sp theo yêu cầu 0932668186 Tuấn.

Check processing to border and clashes machine in Catia V5 Hass VR-11

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.