Best-Selling JSWJ450EIII used Injection Molding Machine for Cancun Importers

Best-Selling JSWJ450EIII used Injection Molding Machine for Cancun Importers Detail:

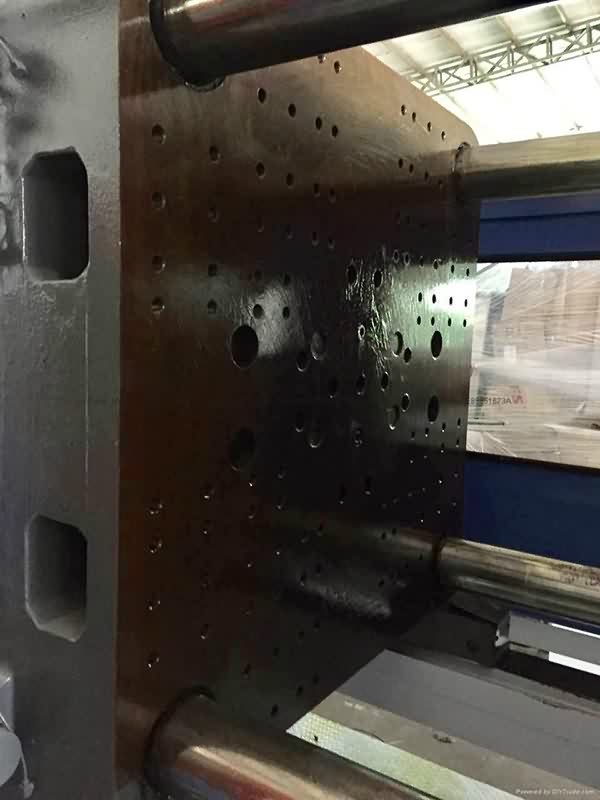

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Best-Selling JSWJ450EIII used Injection Molding Machine for Cancun Importers, The product will supply to all over the world, such as: Montpellier , Egypt , UAE , We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

Laser engraving stainless steel, brass, aluminum (iPhone, iPad ), iron, gold, silver, titanium and metal,laser engraving plastic, marble, ceremic etc. China industrial fiber laser engraving machine manufacturer. Desktop laser engraving machine for metal laser engraving and plastics marking. Laser engraving logo, text, QR code, bar code, serial number. Looking for distribuotrs and users all over the world.

https://laser-engraving-machine.com

https://toplasertech.com

https://prolasertech.com

Industrial Laser Engraving Application:

Electronic Components: Resistors, Capacitors, Chips, Printed Circuit Boards, Computer Keyboard, etc.

Mechanical Parts: Bearing, Gears, Standard Parts, Motor, etc.

Instrument: Panel Board, Nameplates, Precision equipment, etc.

Hardware Tools: Knives, Tools, Measuring Tools, Cutting Tools, etc.

Automobile Parts: Pistons and Rings, Gears, Shafts, Bearings, Clutch, Lights, etc.

Daily Necessities: Handicrafts, Zipper, Key Holder, Sanitary Ware, etc.

TopLaserTech Laser Engraving System manufactures a full range of CO2 and Fiber laser marking machine, laser engraving machine and laser cutting machine powered by world-leading laser brands such as IPG, SPI, Synrad, Coherent, GSI and RECI.

TopLaserTech Laser Machines bring you new concepts of industrial fiber laser engraving machine and laser marking machine, CO2 laser engraving machine and laser cutting machine - proudly designed and built right here in China.

If you are interested in our laser engraving machines, welcome to contact us for prices, videos, specifications and more. Looking for distributors and users all over the world.

***********************************************************

TopLaserTech

leo@toplasertech.com

skype: service@toplasertech.com

mobile/whatsapp/viber/Wechat: +86-18672776295

https://laser-engraving-machine.com

https://toplasertech.com

https://prolasertech.com

plastic reprocessing plant Mumbai, model EP 100

Original manufacturer of Plastic recycling machinery India

Send inquiry for plastic reprocessing plant Mumbai to: europack1@gmail.com

Find more information on plastic reprocessing plant India on: europack1@gmail.com

Europack Machines is a professional plastic reprocessing plant manufacturer in India, we design and manufacture Plastic recycling machinery India based on your requirement. We produce a wide range of Plastic recycling machinery India, including die face cutting, water ring pelletizer, under-water pelletizer, spaghetti (noodle type) pelletizer...

The main feature of Model plastic reprocessing plant India is shredder integrated.

EUROPACK manufactures Plastic recycling machinery India with higher and lower capacity available from 80~900 kg/hr.

Plastic recycling machinery produces high quality pellets. The produced pellets from Plastic recycling machinery can be put directly back to the production line.

High efficiency machine de recyclage du plastique for post-industrial packaging film, with shredder integrated which eliminates the need to pre-cut material.

machine de recyclage du plastique is very suitable for recycling material PE(HDPE and LDPE) and PP.

Plastic recycling machinery is a perfect equipment for blown film factories to recycle its own in-house waste.

plastic reprocessing plant is very suitable for recycling material PE(HDPE and LDPE) and PP.

plastic reprocessing plant is a perfect equipment for blown film factories to recycle its own in-house waste.

Applicable material for Plastic recycling machinery :

HDPE film

LDPE film

PP waste bag

HDPE edge trim waste

LDPE edge trim waste

T-shirt bag cut off

PP raffia

Foam

PE sheet

PE Flake

Complete film roll

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.