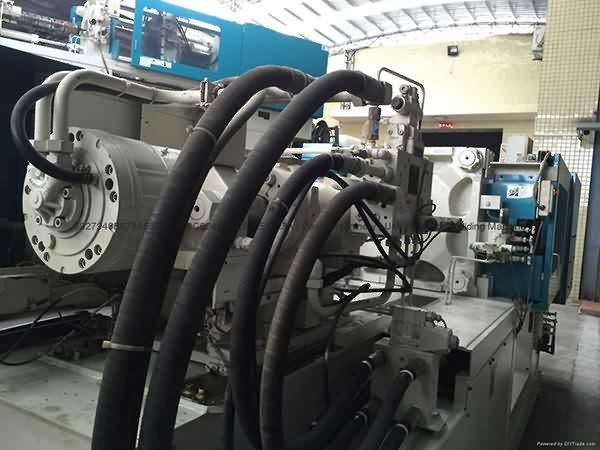

Best-Selling Mitsubishi 160t used Injection Molding Machine for Madras Manufacturer

Best-Selling Mitsubishi 160t used Injection Molding Machine for Madras Manufacturer Detail:

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

"Based on domestic market and expand overseas business" is our development strategy for Best-Selling Mitsubishi 160t used Injection Molding Machine for Madras Manufacturer, The product will supply to all over the world, such as: Bandung , Czech republic , Slovak Republic , Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

Manual Plastic Embossing Machine Credit Card Embosser

Delta Optics Technologies is a Singapore company founded by Dr. Liu Xiang Dong and Lee Kam Sung in 2004 to support the optical & molding industries with;

1. state-of-the-art diamond direct cut steel technology supplement by a wholesome proprietary applications software

2. hardware and process knowhow such as DOT Freeform Profile+ CAM for generating freeform profile and pre-molding thermal shrinkage profile compensation

3. Diamond Tool Re-sharpening machine.

Numerous quantities of hardened stainless steel optical inserts have been produced since.

All Rights Reserved https://deltaoptics.com

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.