Best-Selling Multiplas 200t (wide platen) Double Colour used Injection Molding Machine to Maldives Manufacturers

Best-Selling Multiplas 200t (wide platen) Double Colour used Injection Molding Machine to Maldives Manufacturers Detail:

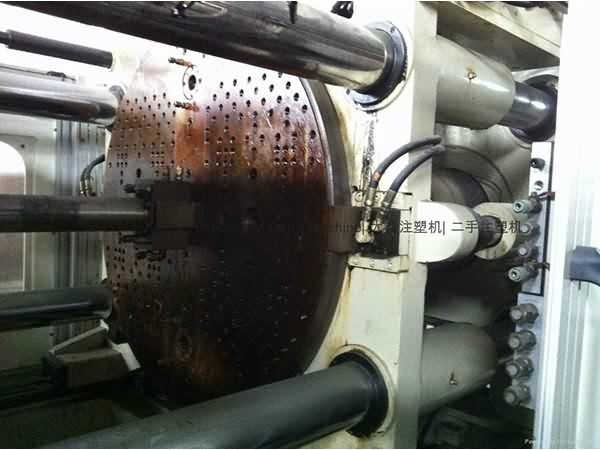

Taiwan Multiplas 200t (wide platen) Double Colour used Plastic Injection Molding Machine

Model: DCM-200T-2C

Clamping force: 200t

Tie bar distance: 940x490mm

Screw diameter(A): 24mm

Shot Weight (A): 60g.

Screw diameter(B): 27mm.

Shot Weight (B): 80g.

Year: 2010.

Motor: 45kw.

Daylight Opening(Max): 800mm.

Machine come with accumulators, two hydraulic clamp tank. It is in very good working condition. It is a much bigger machine that the usual 200t. Interested buyers are welcome to inspect machine anytime.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Best-Selling Multiplas 200t (wide platen) Double Colour used Injection Molding Machine to Maldives Manufacturers, The product will supply to all over the world, such as: azerbaijan , Bhutan , Kuala Lumpur , We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034473?

injection blow molding machine is ideal machine to produce bottles from 3ml to 1000ml small plastic hollow containers with HDPE,LDPE,PP,PS..... THE bottles ...

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!