Big Discount Multiplas 200t (wide platen) Double Colour used Injection Molding Machine Wholesale to Sevilla

Big Discount Multiplas 200t (wide platen) Double Colour used Injection Molding Machine Wholesale to Sevilla Detail:

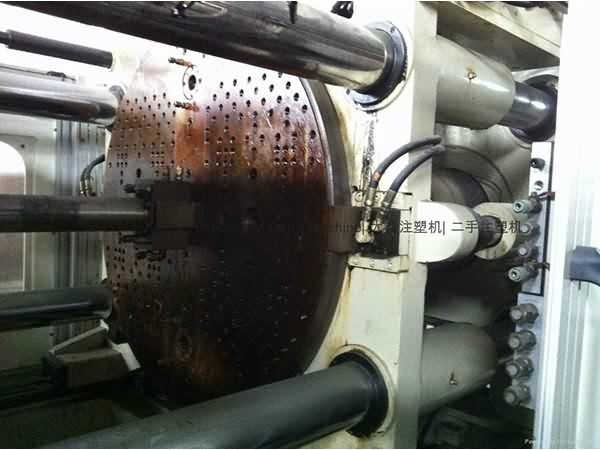

Taiwan Multiplas 200t (wide platen) Double Colour used Plastic Injection Molding Machine

Model: DCM-200T-2C

Clamping force: 200t

Tie bar distance: 940x490mm

Screw diameter(A): 24mm

Shot Weight (A): 60g.

Screw diameter(B): 27mm.

Shot Weight (B): 80g.

Year: 2010.

Motor: 45kw.

Daylight Opening(Max): 800mm.

Machine come with accumulators, two hydraulic clamp tank. It is in very good working condition. It is a much bigger machine that the usual 200t. Interested buyers are welcome to inspect machine anytime.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Big Discount Multiplas 200t (wide platen) Double Colour used Injection Molding Machine Wholesale to Sevilla, The product will supply to all over the world, such as: Nicaragua , Macedonia , Burundi , Providing Quality Items, Excellent Service, Competitive Prices and Prompt Delivery. Our products and solutions are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

The wood plastic composite WPC profile machine including SJMS 65/132 conical double screw extruder,mold,vacumm sizing platform,hual-off device,cutter,stacker. The machine can produce the WPC outdoor floor,decking,etc.The auxiliary equipment including wood milling machine,mixer,WPC granulating machine,cursher,sander,embosser,brushing machine.

Based on the industry-leading HyCAP™ platform, our next generation beverage closures system is built to work together – with increased productivity, built-in intelligence and improved energy efficiency.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!