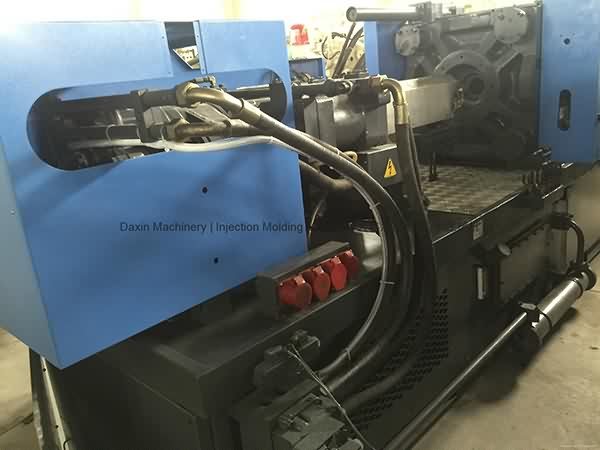

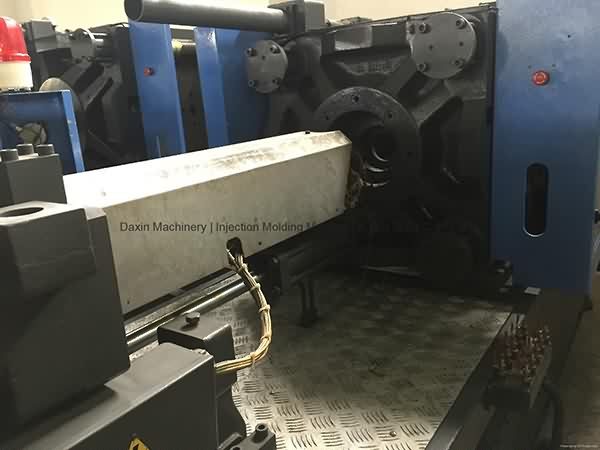

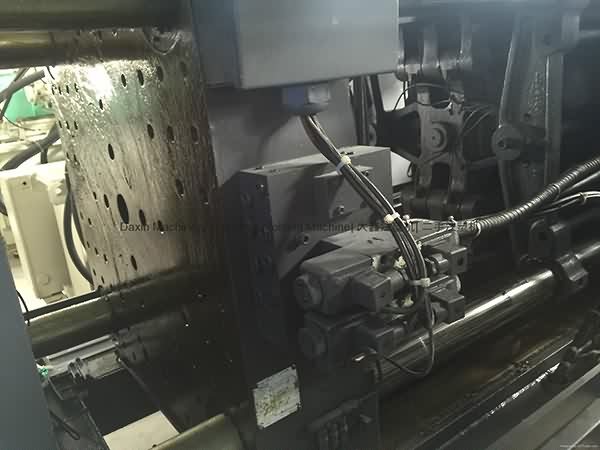

Big discounting Haitian HTF200W2 used Injection Molding Machine Wholesale to Ukraine

Big discounting Haitian HTF200W2 used Injection Molding Machine Wholesale to Ukraine Detail:

Haitian 200t used injection molding machine.

Youtube Video: https://youtu.be/9icUR6v9ilQ

Model: HTF200W2.

Year: 2006.

Screw diameter: 55/50mm.

Tie bar spacing: 520x520mm.

Two units for sale. Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

www.daxin88.com

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

"Based on domestic market and expand overseas business" is our development strategy for Big discounting Haitian HTF200W2 used Injection Molding Machine Wholesale to Ukraine, The product will supply to all over the world, such as: Madagascar , Thailand , Oman , Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

Double Shot injection or 2K moulding is referring to injection 2 material at the same time. This technique will help to save some assembly jobs.

Disney Collector brings you Play-Doh Peppa Pig stampers with Daddy pig, Mummy pig, Peppa pig and George pig stamps. In this video I'm also using the Talking Car Picnic Adventure.

Music from Kevin Macleod.

Disney Frozen Magic Color Changers Anna Coronation Dress.

Disney Frozen Anna Elsa Sleepover at Barbie Glam House.

Princess Sofia Royal Prep Academy Magical Talking Castle.

Play-Doh Meal Makin' Kitchen Princess Sofia the First.

Frozen Magiclip Glitter Glider Anna Elsa Olaf Magic Clip.

Glitter Glider Castle Set Disney Princess Magic Clip Dolls.

Glitter-Glider Dolls Magic clip Belle Rapunzel Elsa Anna.

Disney Frozen Dress-Up Magnetic Wooden Wardrobe Magnets.

Ariel Floating Fountain Color Changers Mermaid Sisters.

Disney Frozen Royal Closet Anna Elsa & Barbie Carry Case.

Play-doh Sofia the First Royal Tea Party w/ Doc McStuffins:

Disney Frozen Ice Skating Elsa & Ice Skating Princess Anna.

Princess Ariel Rapunzel Slumber Party Sleepover at Barbie.

New Sofia The First Royal Tea Party Picnic Doll 40 Phrases!

NEW Play-Doh Sofia the First Amulet Jewels Vanity Sparkle.

Sleeping Beauty Princess Aurora Color Changing Magic Dress.

https://www.youtube.com/user/DisneyCollectorBR/videos

Play-Doh Disney Princess Belle Royal Tea Party playdough.

https://www.youtube.com/user/DisneyCollectorBR/videos

Disney Princess Cinderella Royal Tea Party Time Belle.

https://www.youtube.com/user/DisneyCollectorBR/videos .

.

Check out reviews from Toycollector Blucollection at:

https://www.youtube.com/user/Blucollection .

Click to Subscribe DCTC Toys-Collector Unboxing Channel:

https://www.youtube.com/DCtoysCollector

Assista ao Canal Brasileiro de Brinquedos e Bonecas.

https://www.youtube.com/BrinquedoseBonecas

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.