Bottom price Nanrong 250t used Injection Molding Machine Export to Marseille

Bottom price Nanrong 250t used Injection Molding Machine Export to Marseille Detail:

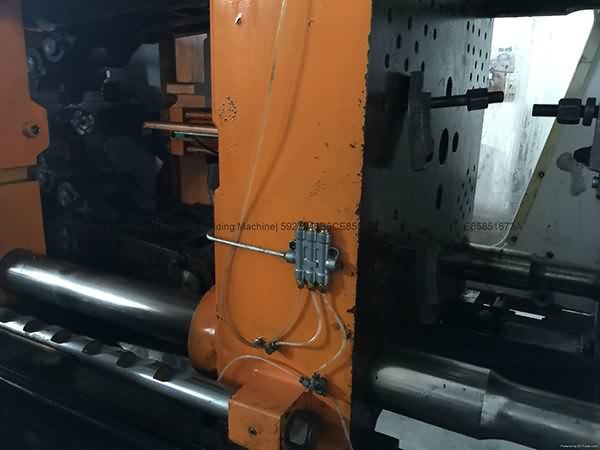

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We are convinced that with joint endeavours, the small business between us will bring us mutual benefits. We could assure you products quality and competitive selling price for Bottom price Nanrong 250t used Injection Molding Machine Export to Marseille, The product will supply to all over the world, such as: Namibia , Vietnam , Zurich , We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

More info: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300033068?OpenDocument&ln=en&origin=YouTube Email: ...

related video: https://www.youtube.com/watch?v=y9HS9sb22Mw

contact us by

support@cnheattransfer.cn / chloe@asia-print.com

Whatsapp / Tel: +86-13728059112

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!