Bottom price Niigata 180t used All-electric Injection Molding Machine for United States Factories

Bottom price Niigata 180t used All-electric Injection Molding Machine for United States Factories Detail:

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

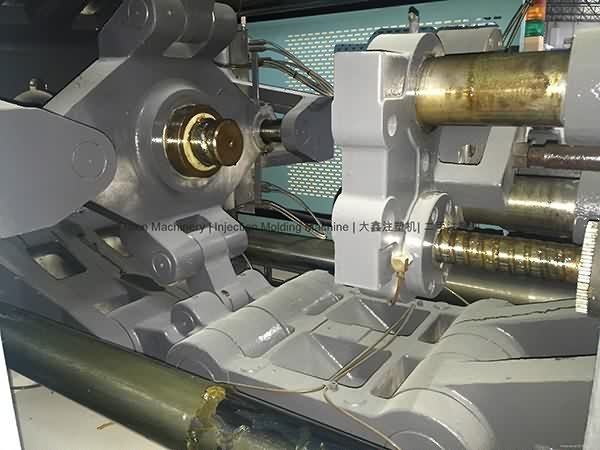

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Bottom price Niigata 180t used All-electric Injection Molding Machine for United States Factories, The product will supply to all over the world, such as: Philippines , Russia , Irish , We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

**** FOR FURTHER INFORMATION PLEASE VISIT US ON WWW.PMCMACHINERY.COM OR SEND US AN EMAIL TO SALES@PMCMACHINERY.COM ****

樺欽HC-280四缸/柱內560/1997年/曲手+模板104年有全新整修/盟立電腦/目前做PC塑料.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.