Cheap price Haitian 160t used Injection Molding Machine Supply to Melbourne

Cheap price Haitian 160t used Injection Molding Machine Supply to Melbourne Detail:

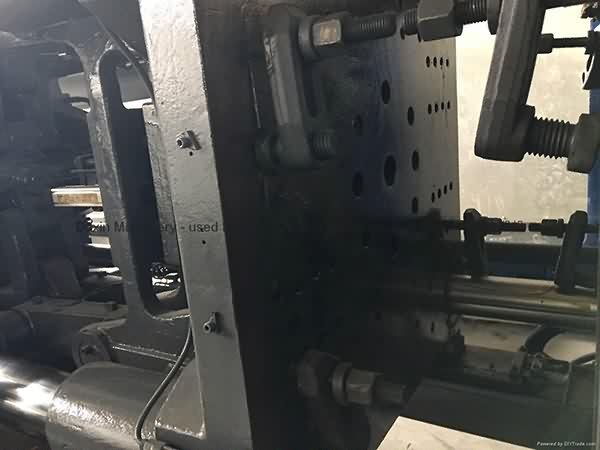

Haitian 160t used Injection Molding Machine

Model: SA1600/540v.

Year: 2010.

Screw: B-D38.

Tie bar spacing: 460mm.

Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions continuously. It regards prospects, success as its personal success. Let us build prosperous future hand in hand for Cheap price Haitian 160t used Injection Molding Machine Supply to Melbourne, The product will supply to all over the world, such as: Rotterdam , Uruguay , Nairobi , We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Automatic Bottle Making Machine

More info: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300033734?OpenDocument&ln=en&origin=YouTube Email: ...

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!