Cheapest Factory JSW 50t All-Electric used Injection Modling Machine to Afghanistan Factories

Cheapest Factory JSW 50t All-Electric used Injection Modling Machine to Afghanistan Factories Detail:

JSW 50t All-Electric Used Injection Molding Machine

Model: JSWJ50ELIII.

Year: 2015.

Screw diameter: 20mm.

Tie bar spacing: 310x31010mm.

Machine is driven by electricity. It is in very good running condition. Interested customer can visit our warehouse to inspect and test machine running.

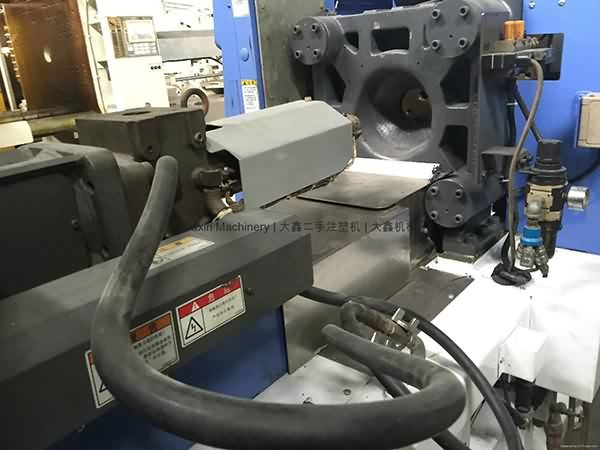

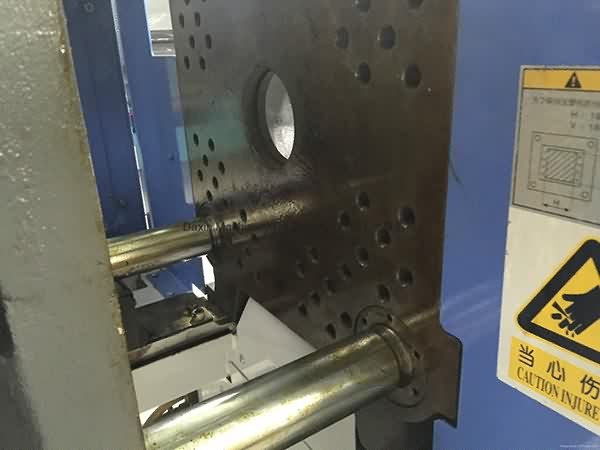

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Our company has been concentrating on brand strategy. Customers' pleasure is our greatest advertising. We also source OEM service for Cheapest Factory JSW 50t All-Electric used Injection Modling Machine to Afghanistan Factories, The product will supply to all over the world, such as: Latvia , Guatemala , Greek , We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

MMC has been supplying cap slitters and TE band inverting machine systems to the closure industry for many years and has advanced the field through innovative machine design.

a) Knotched Knife Slitting Technology

Rotary Cap Slitting machines score the side wall of your plastic closure with arched slitting blade. The slitting blade has intermittent interruptions that will leave a predetermined amount of bridges to hold the Tamper Evident Band to the closure. When the closure is removed from the container for the first time, the bridges break, leaving the band on the neck of the container and demonstrating visual point of purchase tamper evidence to the consumer.

b) Cut-to-post Slitting Technology

A series of ribs are molded into the inner wall of the closure, which will eventually become the bridges that break during closure removal. The closure is rotated against a stationary blade, gradually slicing through the side wall until the blade reaches the molded-in posts.

c) Band Inverter

MMC has launched the CMBF product series to streamline the Tamper Evident Band folding and Band inverting operation. Our unit is a fully automatic multiple head continuous motion machine which is able to fold in the Tamper Evident Band retaining feature allowing the container neck to grip this feature.

For more information, please visit our website

www.mmcpackaging.com

This is a video of one of my injection molding machines for making Soft plastic Fishing Lures. Any questions feel free to ask. More videos coming soon..

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!