Cheapest Factory Toshiba IS650GT Used Injection Molding Machine to Zambia Factories

Cheapest Factory Toshiba IS650GT Used Injection Molding Machine to Zambia Factories Detail:

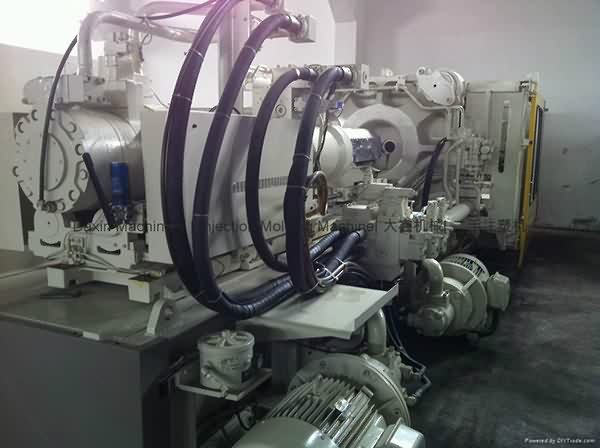

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Cheapest Factory Toshiba IS650GT Used Injection Molding Machine to Zambia Factories, The product will supply to all over the world, such as: Uruguay , Latvia , Belgium , Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we've got got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

For more than 25 years, R&B Plastics Machinery (www.rbplasticsmachinery.com) has excelled at working with companies to develop unique and creative ...

FarEast packaging machine co.,ltd professional produce Automatic shopping bag making machine,t-shirt bag making machine,plastic bag making machine.

https://www.fareastmachine.com

https://www.blownfilmextruder.com

fareastmachine@hotmail.com

sales@fareastmachine.com

Tel:0086-131-8682-7582

Fax:0086-577-56846789

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.