Cheapest Price Hwa Chin 160t two-color used Injection Molding Machine Wholesale to Mecca

Cheapest Price Hwa Chin 160t two-color used Injection Molding Machine Wholesale to Mecca Detail:

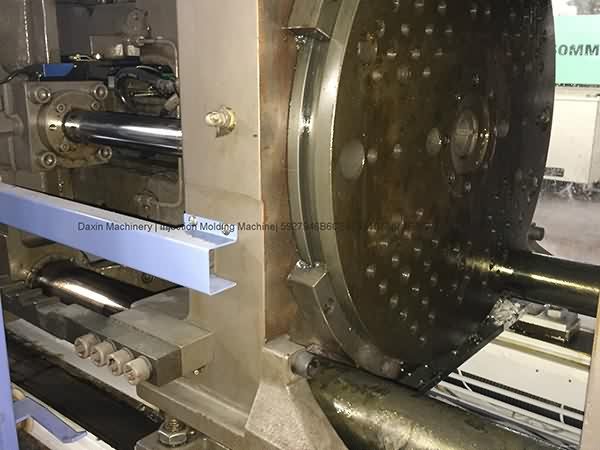

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for Cheapest Price Hwa Chin 160t two-color used Injection Molding Machine Wholesale to Mecca, The product will supply to all over the world, such as: Sevilla , Argentina , Belgium , Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

injection blow molding machine is ideal machine to produce bottles from 3ml to 1000ml small plastic hollow containers with HDPE,LDPE,PP,PS..... THE bottles ...

ENGEL clearmelt technolgy. A thin layer of PUR is injected in the mold to cover the plastic part and to give high gloss and anti scratch properties to the molded ...

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!