Cheapest Price Toshiba IS650GT Used Injection Molding Machine Export to Singapore

Cheapest Price Toshiba IS650GT Used Injection Molding Machine Export to Singapore Detail:

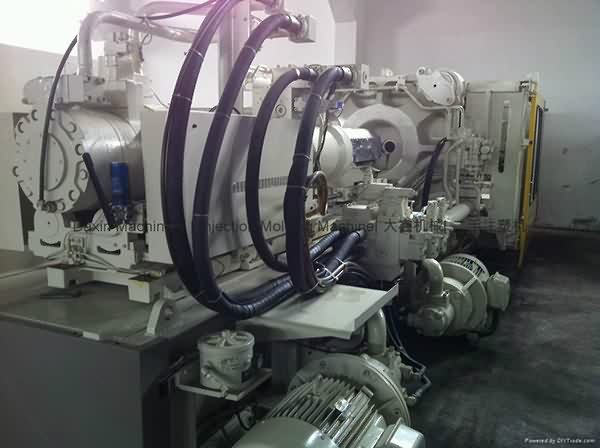

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Cheapest Price Toshiba IS650GT Used Injection Molding Machine Export to Singapore, The product will supply to all over the world, such as: Algeria , Greek , Libya , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

HAITAI PLASTIC INJECTION MOLDING MACHINES IN EXHIBITIONS

A new hybrid 3D printing technique developed at the Wyss Institute at Harvard University, Harvard’s John A. Paulson School of Engineering and Applied Sciences, and the Air Force Research Laboratory combines stretchable conductive inks and electronic components into flexible, durable wearable devices that move with the body and offer increased programmability. Credit: Wyss Institute at Harvard University

To learn more, please visit: https://wyss.harvard.edu/low-cost-wearables-manufactured-by-hybrid-3d-printing

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!