China Factory for CLF-1000T (servo) used Injection Molding Machine to Roman Manufacturers

China Factory for CLF-1000T (servo) used Injection Molding Machine to Roman Manufacturers Detail:

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

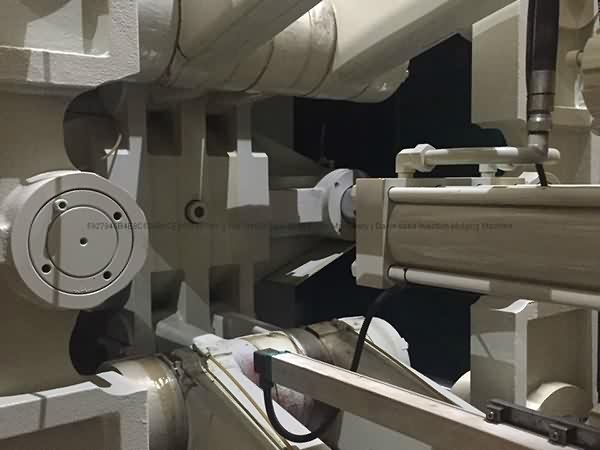

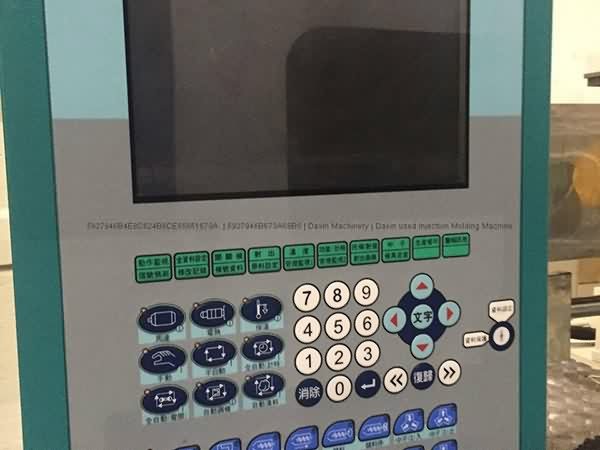

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for China Factory for CLF-1000T (servo) used Injection Molding Machine to Roman Manufacturers, The product will supply to all over the world, such as: Niger , Pakistan , Czech Republic , Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

ما كينه حقن صغيره.

Small Size Automatic Plastic Thermoforming Machine for food boxes is produced by our factory Ruian Bokai Machinery Co.,LTD

This thermoforming machine is fully automatic working from sheet roll feeding, heating, forming, hole punching, trimming&stacking. It is a small machine with less invest,less power requirement, less labor cost and etc.

Webiste:www.bokaimachinery.com

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.