China Factory for Haitian 120t used Injection Molding Machine to Bolivia Importers

China Factory for Haitian 120t used Injection Molding Machine to Bolivia Importers Detail:

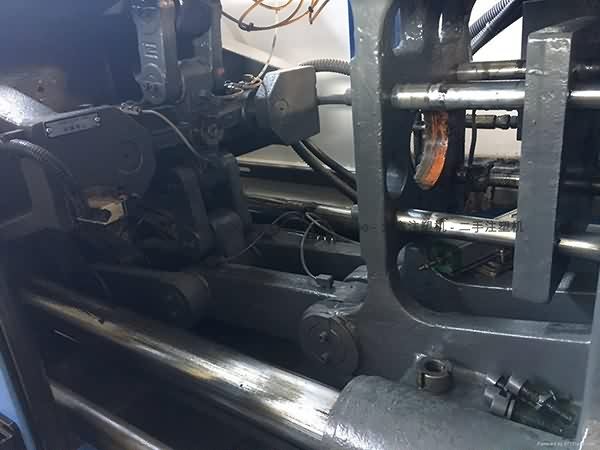

Haitian 120t used Injection Molding Machine

Model: SA1200/370.

Year: 2010.

Screw: A-D34.

Tie bar spacing: 410mm.

Two units. Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for China Factory for Haitian 120t used Injection Molding Machine to Bolivia Importers, The product will supply to all over the world, such as: Lithuania , Armenia , Kuwait , For anyone who is keen on any of our goods right after you view our product list, please really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it's easy, you may locate out our address in our web-site and come to our business for far more information of our products by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

TCM SHREDDER: https://www.tcmshredder.com/ a professional manufacturer, specialize in recycling shredder machine for more than 15years, Our produc ts are applicable for pet bottles, LDPE,HDPE, plastic lumps, ABS plastic, plastic films, mattress spring, etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.singal shaft shredder

2.double shaft shredder

3.plastic crusher

4.plastic pipe shredder

5.four shaft shredder

6.plastic miller

7.plastic pulverzer

https://www.tcmshredder.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Single shaft shredder for film sheet bags, Brazil, mini tcm shredder, Introduction of Single shaft shredder for film sheet bags . Single shaft shredder for film sheet bags is solid and durable., how shredder double cut plastic, Single Plastic Film Shredder, Single Plastic Botswana, heavy duty occ shredder, Single Plastic Film Shredder, Wholesale Various High Quality Single Plastic Film Shredder Products from Global Single Plastic Film Shredder Suppliers and Single, transportable plastic shredder, Single Rotor Shredder, One Shaft Shredder Cameroon, radiators shredder, PROSINO Swing arm Single Rotor Shredder for sale is ideal to shred film, cardboard, wood and textile etc. Reliable quality and excellent service. Inquiry, four shaft shredder pp pe, Single Shredder Machine, China Single Cuba, wood pallet shredder dubble shafts, China Single Shredder Machine manufacturers Select 2017 high quality Single Shredder Machine products in best price from certified Chinese Cutting Machine, shredding cardboard boxes, Single Shaft Shredder PE Film Washing Line Denmark, shredder for plastic film, The single shaft shredder is an optional piece of equipment in our PE film washing line reserved for lower grade films with higher levels of contamination., hdpe shredder machine, shredder integrated recycling machine Algeria, industrial shredders shredding play house parts, Polystar has installed more than 1000 sets of shredder integrated recycling machine worldwide since 1988, working mainly with film and single shaft shredder, prosino shredding, Plastic Film Shredder for Sale, Plastic Film Ethiopia, how to use shredded aluminium scrap, PROSINO Swing arm Single Shaft Shredder and all Double Shaft Shredder are perfect to shred plastic film. It is popular as Plastic Film Shredder. Inquiry, jute shredder, Buy and Sell Used Plastics Dual Rotor or Korea, ubc cans shredder, Used Plastics Dual Rotor and Single Rotor Shredders 23 Size Reduction Used Zeno Single Roll Shredder, SureCut Film and fiber cutting profile., plastic lumps shredding machines wow, single shaft shredder of Plastic Shredder Latvia, paper shredder abs, Quality single shaft shredder find quality Plastic Shredder, Waste Management Plastic Shredder from Zhangjiagang Saiou Machinery Co., Ltd. of China Suppliers, trash shredder big rig, 3E Machinery SINGLE SHAFT SHREDDER Mozambique, shredder plastic film agricultural, SINGLE SHAFT SHREDDER. Model The WT series single shaft shredder is suitable for recycling wide range of materials. It is an ideal machine for plastic, paper, hdpe aluminum shredder, plastic film shredder film shredder Niger plastic film shredder film shredder machine single shaft shredders, US $ 18, 000 25, 000 Set, New, Henan, China Mainland, from Zhengzhou Zhengyang China Film and bags double single shaft Netherlands Film and Bags Double Single Shaft Shredder Machine This double single shaft shredder machine is designed and manufactured by our company with advanced technology VISION Series Single Shaft Shredders Philippines VISION Series Single Shaft Shredders are small to medium size reduction machines suitable for processing a wide range of materials to a uniform particle Single Shaft Shredder Double Pakistan Zibo United Tech Machinery Co., Ltd. is best Single Shaft Shredder, Double Shaft Shredder and Granulator supplier, we has good quality products service from Shredder Plastic Portugal Description. ASGs single shaft shredder with push drawer is a robust, yet versatile size reduction equipment capable of shredding a large range of material single shaft shredder Saudi Arabia Guangzhou 3E Machinery Co., Home single shaft shredder. Product Name: for shredded material as film, woven bags or nylon, ABS and Shaft Shredder SR600Series Arab Single Shaft Shredder SR600Series. Single shaft shredder, shredding paper wood ABS Film watch video Single shaft shredder, shredding blue pail watch videowaste plastic Shredder, PE film shredder, ton Vietnam Plastic shredder The plastic shredders are especially suited to quietly size reduce most types of plastic including bottles, films, ton bags, barrels

My first time in China. I was enlightened to see this.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.