China Factory for Nanrong 250t used Injection Molding Machine for Kuwait Importers

China Factory for Nanrong 250t used Injection Molding Machine for Kuwait Importers Detail:

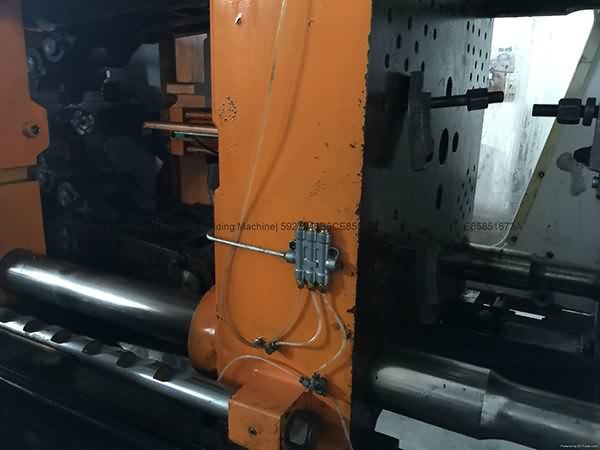

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

We pursue the administration tenet of "Quality is remarkable, Services is supreme, Status is first", and will sincerely create and share success with all customers for China Factory for Nanrong 250t used Injection Molding Machine for Kuwait Importers, The product will supply to all over the world, such as: Amman, Marseille , Brisbane , We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

Company website: www.cnmolder.com For any suggestion please contact focaremould@yahoo.com Thank you. Lucia.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.