China Factory for Toshiba 1300t (wide platen) used Injection Molding Machine for Malaysia Factory

China Factory for Toshiba 1300t (wide platen) used Injection Molding Machine for Malaysia Factory Detail:

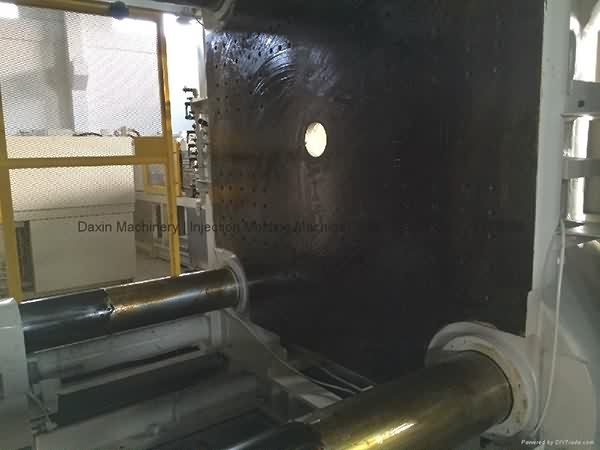

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of China Factory for Toshiba 1300t (wide platen) used Injection Molding Machine for Malaysia Factory, The product will supply to all over the world, such as: belarus , Armenia , India , We have been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

Manual Plastic Embossing Machine Credit Card Embosser

**** FOR FURTHER INFORMATION PLEASE VISIT US ON WWW.PMCMACHINERY.COM OR SEND US AN EMAIL TO SALES@PMCMACHINERY.COM ****

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!