China Gold Supplier for Chen Hsong Super Master SM250TS used Injection Molding Machine Export to Slovakia

China Gold Supplier for Chen Hsong Super Master SM250TS used Injection Molding Machine Export to Slovakia Detail:

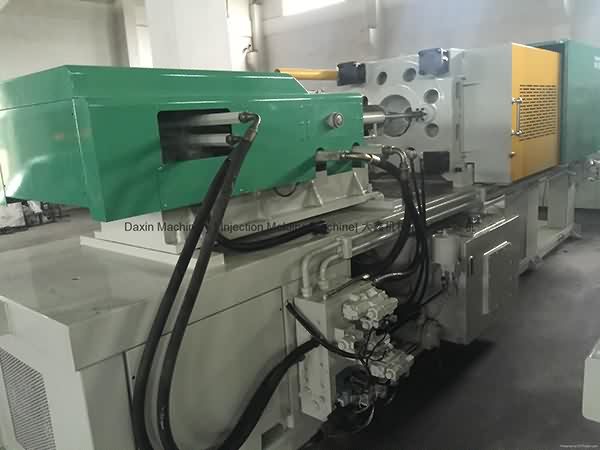

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for China Gold Supplier for Chen Hsong Super Master SM250TS used Injection Molding Machine Export to Slovakia, The product will supply to all over the world, such as: Bogota , New York , Washington , Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

Fully-automatic PET Bottle Blow Molding Machine adopt Siemens PLC & Touch Screen,Germany Festo pneumatic system,Japan Mitusbishi Servo Motor ,high ...

Robot taking parts out of Plastics Injection Molding machine. It removes part, degates (cuts) the runner, drops runner on scrap conveyor, then places parts on ...

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!