China Gold Supplier for Niigata 180t used All-electric Injection Molding Machine to St. Petersburg Manufacturers

China Gold Supplier for Niigata 180t used All-electric Injection Molding Machine to St. Petersburg Manufacturers Detail:

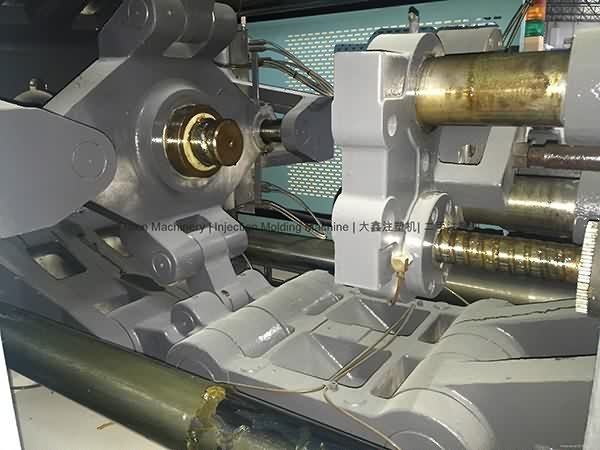

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization for that long-term to establish jointly with customers for mutual reciprocity and mutual gain for China Gold Supplier for Niigata 180t used All-electric Injection Molding Machine to St. Petersburg Manufacturers, The product will supply to all over the world, such as: Accra , Iraq , Macedonia , Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

What's App: +86 159 6280 7500

Wechat: bobomachine

Email: sotu@bobomachine.com

Tel: 0086 513 8907 7744

Fax: 0086 513 8907 7745

Website: www.bobomachine.com

Stainless steel cutlery, flatware, fork, knife and spoon making machine from BOBO Machine, China.

Contact us for more detailed information.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034473?

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,