China Manufacturer for Chuan Lih Fa CLF-950TX used Injection Molding Machine Wholesale to Nepal

China Manufacturer for Chuan Lih Fa CLF-950TX used Injection Molding Machine Wholesale to Nepal Detail:

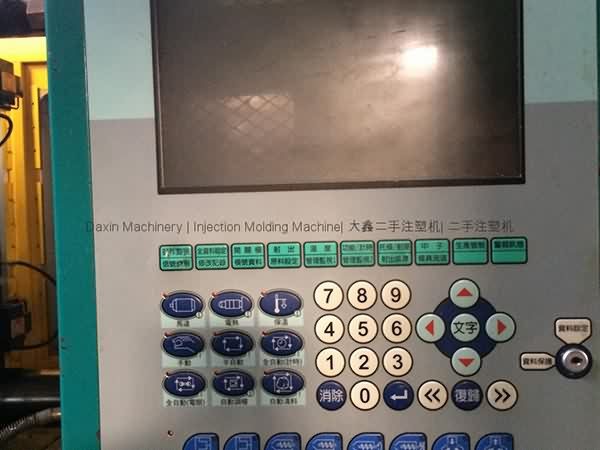

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Precision of Plastic Machining

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of China Manufacturer for Chuan Lih Fa CLF-950TX used Injection Molding Machine Wholesale to Nepal, The product will supply to all over the world, such as: Japan , Gabon , Jeddah , because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

Used vest / t-shirt bag making machine for sale in India. https://www.machinesale.in/Used-Plastic-Extruder

Wetec Europe Otomasyon

www.wetec.com.tr

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.